Industrial Textile Cutting

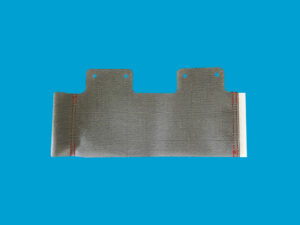

Precision Textile Die and CAD Cutting

program and die-cut Custom Fabric, Filter, and Pad Solutions for Diverse Industries

PROGRAM CUTTING

For over six decades, Fairway Products has been a leading provider of textile die cutting and textile CAD cutting services. Specializing in precision die-cut and program-cut components, we focus on high-quality fabrics, filters, and pads for industries such as medical, automotive, and pharmaceutical. Our commitment to quality, innovation, and customer satisfaction has made us a trusted partner to businesses worldwide.

Leveraging advanced textile CAD cutting systems, our expert team ensures the most efficient use of materials, delivering cost-effective and high-quality die-cut components. From intricate shapes to complex patterns, we offer customized solutions to meet your exact specifications. Whether you need small-batch prototypes or large-scale production runs, our textile die cutting capabilities ensure we can handle your project efficiently and with precision.

DIE CUTTING

Our Filpaco filter papers, renowned for their exceptional performance and versatility, are available in various grades and can be custom-cut to meet the unique requirements of your filtration process. From fine particulate removal to liquid clarification, our filter papers provide the ideal solution, tailored to fit your specific application.

In addition to textile die cutting and textile CAD cutting, we offer a full suite of services to support your project, including expert textile product development services. We also assist with material sourcing and slitting, helping you select the optimal materials for your application. Our prototyping capabilities enable you to visualize and refine your product before moving to full-scale production. Moreover, our experienced technicians are always available to provide ongoing support, ensuring your complete satisfaction.

The Power of Fairway

Do you need custom fabric, filter, or pad solutions? Fairway Products offers a comprehensive die cutting and program cutting service for various industries. We utilize advanced technology and expertise to deliver precise cuts, reduced waste, and efficient production. From medical dressings to automotive gaskets, our capabilities cater to a wide range of applications. Explore the benefits of Fairway’s precision cutting and discover how we can streamline your manufacturing process.

Medical & Hygiene

Dressings, filters, swabs, wipes, bandages

Seating & Seat Covers

Buses, Airplanes, RVs, ATVs, Trucks

Filtration

Dust collection, oil mist, fabric/textile pre-filters, HVAC filters

Industrial Manufacturing

Gaskets, wipes, insulation

Precision Cutting:

- Gerber and Pathfinder cutters for accurate results

- Handles materials up to 90″ wide and 1.5″ thick

- Drilled holes from 1mm to 6mm

- Tension-free spreading for textiles

Custom Solutions:

- No tooling required for program cutting

- Easy program modifications

- Steel rule dies for intricate designs

- Multi-ply cutting capabilities

Material Versatility:

- Processes a wide range of textiles, non-wovens, films, and papers

- Cuts materials up to 2″ thick (slitting)

- Handles roll widths up to 104″ (slitting & rerolling)

Advanced Capabilities:

- Nesting for material optimization

- Slitting and rerolling with tight tolerances (+/- 1.5mm)

- Duplex slitting for thin films and paper

Benefits

Key Capabilities

Program Cutting

• Gerber and Pathfinder cutters

• Material widths up to 90″ wide

• Textile layers up to 1.5 “

• Computer guided technology

• Drilled holes 1mm-6mm

• Tension free spreader of textiles

• Easy Cut program modifications

• No tooling required

• Process a wide range of textiles

Die-Cutting

• Traveling head die cut press

• Multi-ply cutting capability

• 39″ X 39″ cutting head

• Material width up to 78″

• Steel rule dies

• Nesting capabilities

Converting

• Material widths to 70″

• Cut part size up to 70″ X 50″

• Steel rule dies

• Multi-ply material cutting

Slitting

• Processes material up to 2″ thickness

• Utilizes air score slitter knives

• Heavy duty unwind capability

• Processes material on 3″ cores

• Roll width to 60″

Slitting & Rerolling

• Wovens, non-wovens, vinyls, carpet, screen, and plastic mesh

• Roll widths up to 104″

• Roll diameters up to 53″

• Core sizes 2″-6″ on the unwind

• Core sizes 2″-3″ on roll put ups

• Cut tolerances +/- 1.5mm

Duplex Slitting

• Unwind diameter up to 55″

• Unwind core size range 3″-7″

• Unwind roll weight up to 4000 lbs

• Rewind diameter up to 31.5″

• Rewind core sizes 2″ & 3″

• Cut widths – 1” min.

• Material: .001 – .010 in thick film (PP. PET, PE), .007 – .017 in thick paper

Materials & Equipment

• PET

• Woven PP

• HDPE

• Paper

• EPDM

• Spun PET

• Woven Screen

• Polyester

• Vinyl

• Leather

• Scrim

• Kevlar

• Foam

• Non-Wovens

• Specialty Fabrics