Applications

Precision Cutting, Endless Possibilities

Transform Your Materials with Our Expert Slitting and Rerolling Services

Fairway Products has a long history in slitting and rerolling, dating back to 1951. The company also has a rich history in developing technical fabrics and textile converting programs.

Fairway slits and rewinds your rolled goods with a quick turnaround time, and stocking capabilities. In addition to converting your existing rolled goods, Great Lakes can source your material at a more competitive price point.

We have access to the Acme Group purchase team to help locate and source unique materials.

Our capabilities and equipment can process a wide variety materials, wovens, knits, paper, films, adhesives, non-wovens – bring it in/we are ready to try it and re-invent the group.

We partner with a large group of vendors and suppliers to expand our offerings and services.

The Power of Fairway

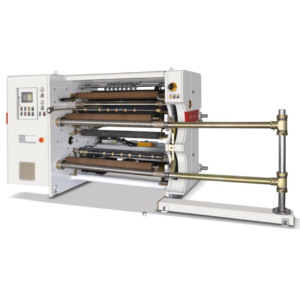

Fairway Products unlocks the full potential of your materials through precision slitting and rerolling. Our state-of-the-art equipment and extensive expertise enable us to transform your raw materials into high-quality, customized products. From automotive components to industrial filtration, our services deliver unmatched precision, efficiency, and cost-effectiveness. Experience the Fairway difference and discover how our solutions can elevate your manufacturing process.

AUTOMOTIVE

Seat covers, headliners, carpets, insulation, sealing tapes

AEROSPACE

Insulation, filtration media, composite materials

CONSTRUCTION

Roofing underlayment, waterproofing membranes, insulation, geotextiles

ELECTRONICS

Insulation, protective films, adhesive tapes

MEDICAL

Surgical drapes, gowns, masks, wound care products

FILTRATION

Air filters, liquid filters, industrial filtration media

PACKAGING

Paper and film for packaging materials

AGRICULTURE

Crop covers, mulch films, geotextiles

Features

Benefits

Slitting and Rerolling Capabilities

- Nylon

- Meshes

- Wearables

- Polyester

- Chromatography Paper

- Electrophoresis Paper

- Blotting Paper

- Food and Lab Grade Paper

- Film

- Chromatography Paper

- Electrophoresis Paper

- Blotting Paper

- Food and Lab Grade Paper

- Film

Materials & Equipment

- Wovens

- Knits

- Paper

- Films

- Adhesives

- Non-wovens

- Spunbond fabrics

- Pointbond fabrics

- Meltblown fabrics

- Lofted media

- Needle punched felts

- Hydroentangled fabrics

- Spunbond polyester filter media

- Spunlace polyester filter media

- Spunbond polypropylene filter media

- SMS polypropylene filter media

- Meltblown polypropylene filter media

- Composite fabrics filter media

- Rayon filter media

- Polyester blend filter media

- Sonic bonded composites

- Layered polyester

- Wet-laid cellulose

- Chem-bond rayon

- Layered polypropylene

- Power-flo depth media

- Nylon

- Meshes

- Wearables

- Polyester

- Chromatography paper

- Electrophoresis paper

- Blotting paper

- Food and lab grade paper

- Film

Key Markets

Case Studies

No post found!