Great Lakes Filters: Driving Filtration Excellence in Automotive Manufacturing and Performance

In the automotive industry, precision, reliability, and innovation are key to success. Great Lakes Filters brings decades of expertise in technical fabrics and filtration solutions designed to optimize performance across automotive applications. From enhancing cabin air quality to protecting engine systems, our products ensure superior performance, longevity, and efficiency.

Our Filtration Solutions for the Automotive Industry

Acme Mills offers a comprehensive range of filtration solutions designed to improve the performance, durability, and efficiency of thermoforming applications. Our specialized solutions include:

Cabin Air Filtration

Advanced filtration media that improves air quality inside vehicles by capturing particulates, allergens, and odors, ensuring a cleaner and more comfortable passenger experience.

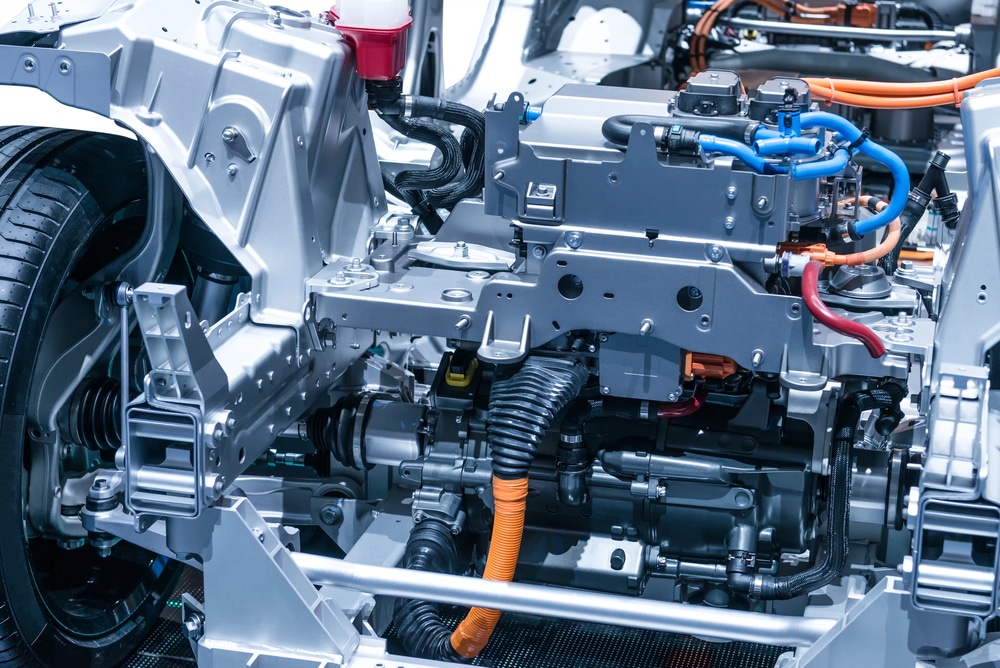

Engine and Fuel Filtration

High-performance filter materials engineered to protect vital engine components from harmful contaminants, promoting efficient operation and extending system life.

Industrial Filtration for Manufacturing Processes

Precision-engineered filters that enhance production line efficiency, such as paint booth filtration, coolant filtration, and air system filters to maintain a clean and optimized manufacturing environment.

Custom Filtration Solutions

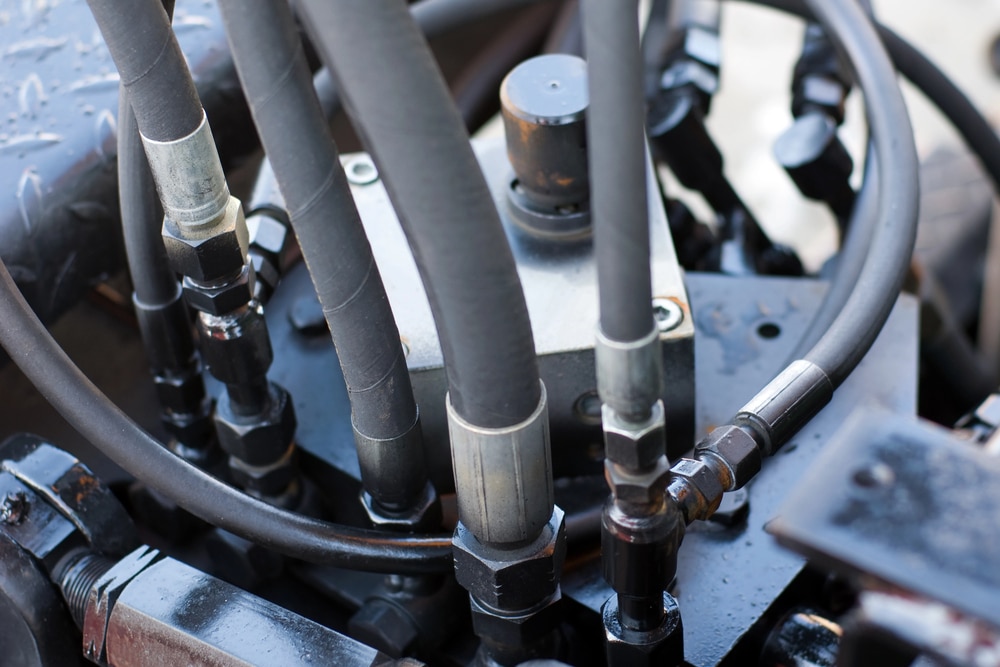

Tailored materials and filtration systems designed to address the unique needs of automotive systems, from hydraulic filtration to fluid management, ensuring optimal performance in every application.

Why Choose Great Lakes Filters for Automotive Filtration?

Applications for the Automotive Industry

Experience the Difference: Automotive Filtration Excellence

Great Lakes Filters is your trusted partner in delivering innovative and reliable filtration solutions for the automotive industry. Discover how our expertise can elevate your operations and support your goals for enhanced performance, reliability, and sustainability.

Needs Assessment & Solutions Summary

Project Specifications

Solution Design

To address these challenges, Great Lakes Filters engineered a set of three filter roll media designed for intermittent use:

Applications & Capacity

Potential Industries

Aerospace Manufacturing

Heavy Equipment and Machinery Production

Industrial Pump and Compressor Manufacturing

Metalworking and Fabrication

Energy and Power Generation Equipment

Marine and Shipbuilding Industries

Manufacturing Details

Composite Construction

The filter rolls were crafted from ISO-certified oleophilic and oleophobic materials.

Customization

The composition and layering of materials were optimized to ensure high performance without premature media blinding.

Batch Testing

Each roll underwent stringent quality control to verify its filtration capacity and durability.

Quality Control Measures

Great Lakes Filters adhered to stringent quality assurance protocols to meet the client’s rigorous pharmaceutical standards: