Industrial Manufacturing

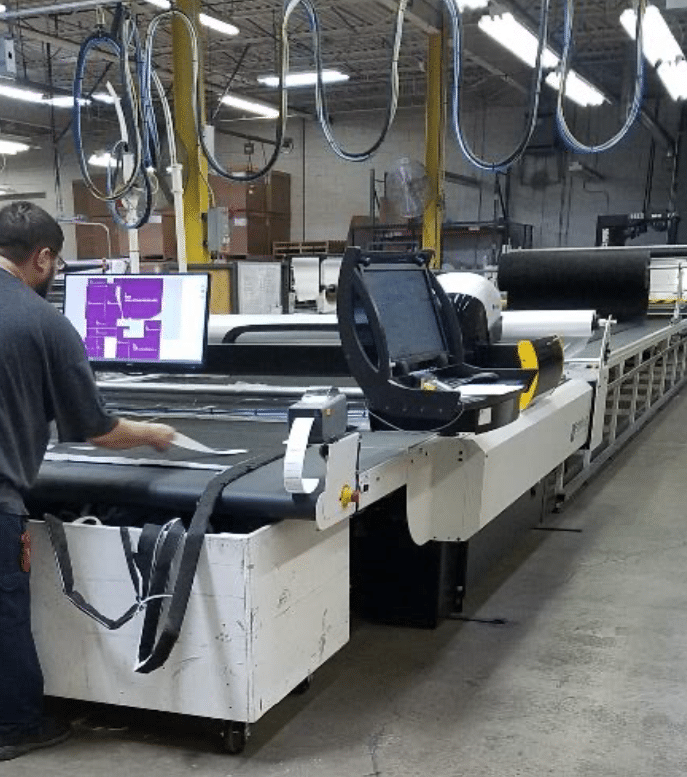

Precision Cutting and Fabrication for Industrial Textiles

Tailored Solutions for Your Business

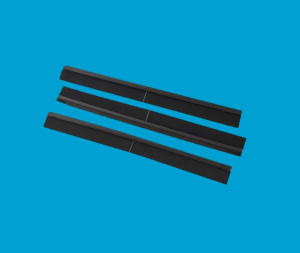

Fairway Products is your trusted partner for precision cutting and fabrication of industrial textiles. Our custom textile cutting services use top tools and skilled hands to bring your ideas to life. We work with care and speed on every job, from slitting nonwoven fabrics to ultrasonic cutting for nonwoven textiles. We also offer contract sewing for heavy materials to help with strong and lasting builds. Whether you need tailor-made seat covers or other custom parts, we manage it all with full focus. Your products will meet top standards every time.

Explore Fairway Products’ Contributions to Industrial Manufacturing Applications:

Key Equipment

Key Services

Industrial Textile Die Cutting

Utilizes advanced CNC machinery to cut fabrics and materials with high precision.

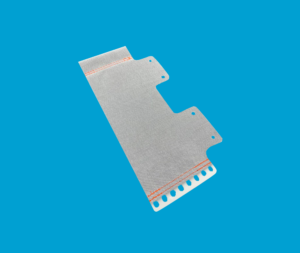

Offers specialized sewing services for commercial and industrial applications.

Offers specialized seaming and sealing services to enhance the durability and functionality of industrial textile products.

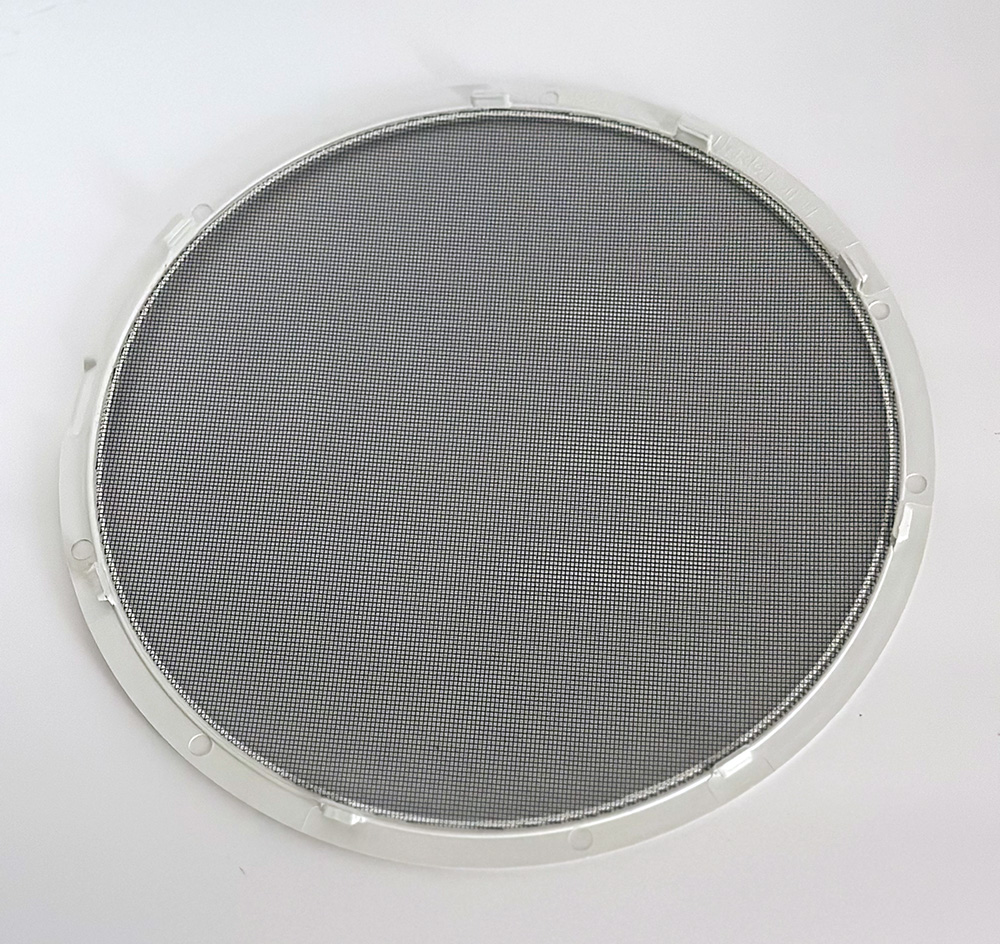

Industrial Slitting & Rerolling

Provides slitting and rerolling services to prepare materials for further processing and production.

Transform Your Ideas into Reality. Contact Us Today!

Fairway Products combines tools, skill, and care to deliver your product the right way. With advanced textile cutting services and ultrasonic cutting for nonwoven textiles, we make sure every job is sharp, smooth, and on time.