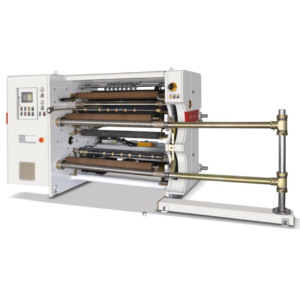

Dri-Tec Duplex Slitter

Introducing the Duplex Slitter Machine

Revolutionizing Material Slitting at Fairway Products

Fairway Products is excited to unveil our latest addition to our advanced machinery lineup: the Duplex Slitter machine. This state-of-the-art machine is designed to elevate our non-woven fabric slitting and industrial roll slitting services, offering improved speed, precision, and cost savings. Read on to learn how the specific features, benefits, and specifications of the Duplex Slitter machine stand out to transform our operations and benefit our clients.

Details

Enhanced Efficiency

Unmatched Precision

Cost Savings

Versatility

Resource Optimization

Why Choose Fairway Products’ Duplex Slitter Machine?

At Fairway Products, we always focus on delivering smart solutions that save time and improve quality. The Duplex Slitter machine shows this promise in action. It supports a wide range of uses, including non-woven fabric slitting and pulp and paper roll slitting, making it a great fit for many industries.

The machine delivers narrow width slit results with great accuracy. These precise cuts help lower waste and save money. It is ideal for industrial roll slitting services, giving our clients reliable output every time.

We also offer advanced support with flatbed die cutting solutions and CNC cutting for cost-effective production. By adding the Duplex Slitter to our services, we stay true to our goal of offering top results with every job.

Whether you work in automotive, industrial, or consumer goods, the Duplex Slitter machine is made to meet your specific needs. Its smart design and consistent results make it a key tool for any job that needs clean and accurate non-woven fabric slitting.