Skip to content

Program Cutting – Pathfinder CNC

Material widths up to 90” wide can be converted

Process a wide range of textiles

Cuts textile layers up to 1.5”

Computer guided technology ensures precise cuts

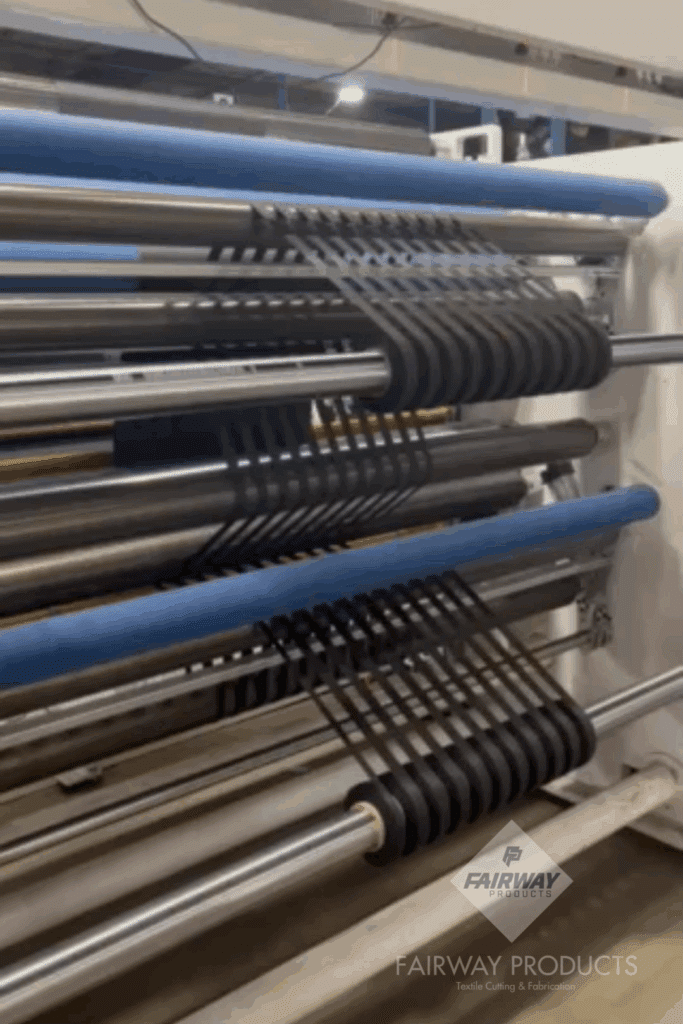

Tension free spreader of textiles

Easy Cut program modifications

Unwind diameter up to 55”

Unwind core size range 3” – 7”

Unwind roll weight up to 4,000 lbs

Rewind diameter up to 31.5”

Rewind core sizes 2” & 3”

Material: .001-.010-inch-thick film (PP, PET, PE), .007 – .017-inch-thick paper

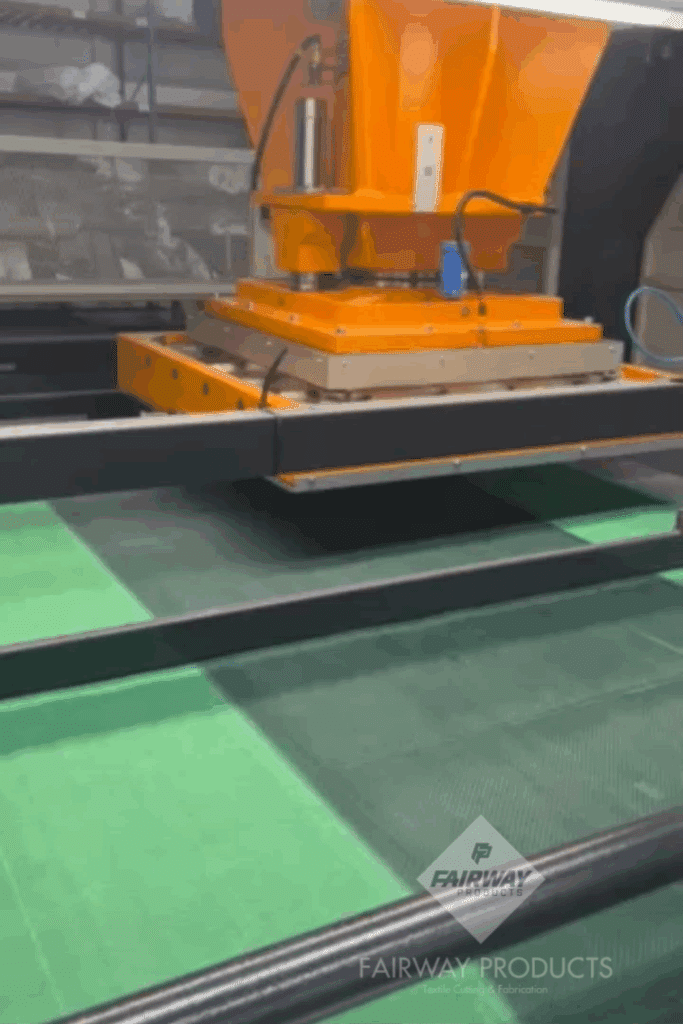

Traveling head die cut press

Multi-ply cutting capability

Material width up to 78” can be converted

Steel rule dies used for precision cutting

Nesting capabilities for ultimate material utilization

Material widths to 70” can be converted

Cut part size up to 70” x 50”

Steel rule dies used for precision cutting

Multi-ply material cutting

Process material up to 2” thickness

Utilize air score slitter knives

Heavy duty unwind capability

Processes material on 3” cores

Core sizes 2” – 6” on the unwind

Core sizes 2” – 3” on roll put ups

Industrial Sew – Juki and Mitsubishi Machines

Walking foot and needle feed options

Capable of sewing heavy textiles

Array of custom attachments for folding and binding

Complex shapes and patterns

Fabric Welding – Sonobond and Miller Weldmaster Machines

Ultra sonic welding of nonwoven materials for custom sealed edges

Heat and pressure welding of vinyls and nonwovens

Heat cutting to eliminate fraying

Cold cutting for heat sensitive materials

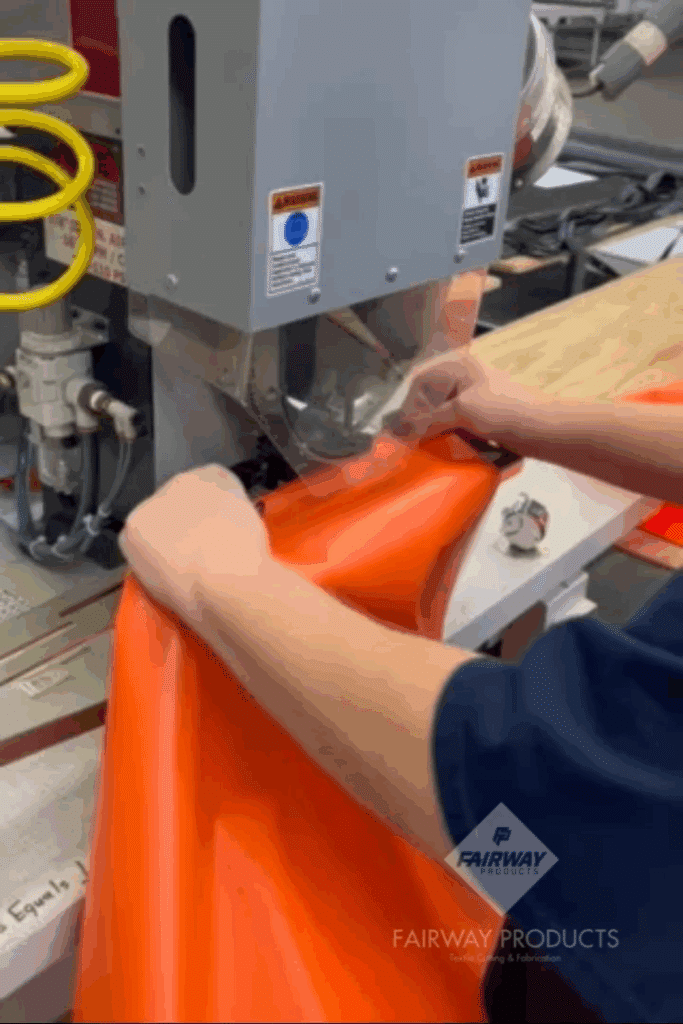

Grommet and snap attachments

Can run various size die sets for grommet sizes

Grommets and snaps of various sizes

Array

(

[0] => https:

[1] =>

[2] => acmemills.com

[3] => equipment-pdf-content

)