Project Specifications

Manufacturing Details

1. Material Selection and Preparation

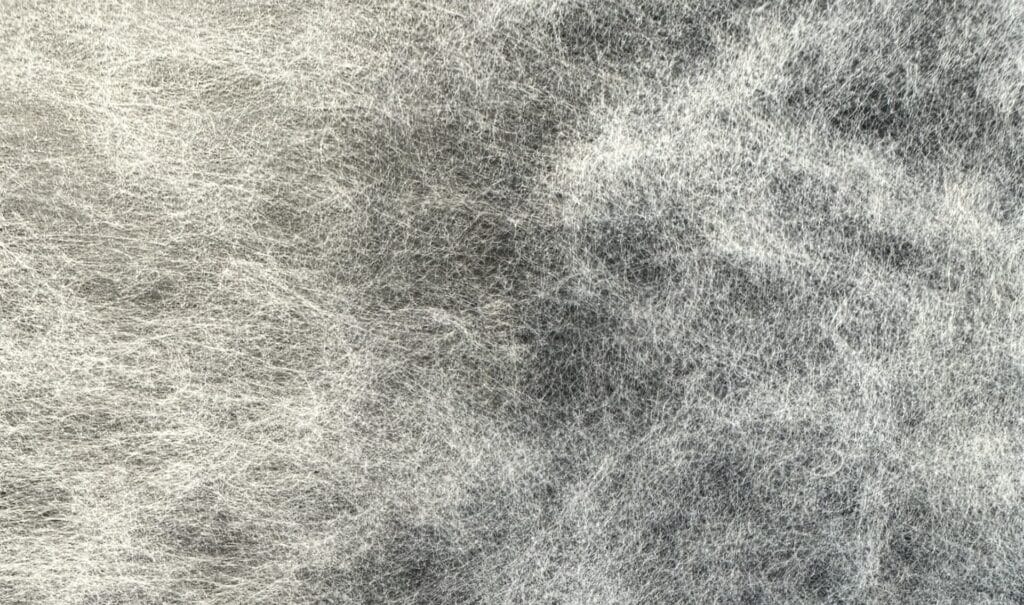

The polyester veils were produced using high-quality polyester fibers. Two variants were tailored to meet the client’s specific requirements:

0.234 oz/yd² veil for lightweight applications.

0.50 oz/yd² veil for applications requiring additional strength and durability.

2. Production Process

Slitting and Re-Rolling: Rolls of polyester material were slit to specified widths and re-rolled for ease of use in the pultrusion process.

Flat Bonding: The material was precision-bonded to ensure uniform density and strength.

Customization: Each roll was labeled and prepared per the client’s exact specifications for direct integration into their production lines.

3. Quality Control

Acme Mills adheres to rigorous quality control measures to ensure consistency and performance:

Material Testing: Polyester fibers underwent tensile strength and weight validation before production.

Visual Inspection: Each roll was inspected for defects, including uneven bonding or visible impurities.

Dimensional Checks: Rolls were verified for uniform width and roll length as per purchase order specifications.

Lot Tracking: Materials were batch-numbered for traceability, ensuring accountability and streamlined resolution of any client inquiries.

Applications & Capacity

Uses and Applications

The veil material supplied by Acme Mills is integral to the pultrusion process, offering the following advantages:

Capacity and Scalability

Acme Mills demonstrated the capacity to scale production efficiently, delivering large quantities of veil material within tight deadlines. The company’s advanced manufacturing capabilities enabled it to handle both small-scale custom orders and high-volume production runs while maintaining quality and precision.

This project highlights Acme Mills’ ability to deliver high-performance textile solutions for automotive interiors. By providing customized warp-knit and spunlace fabrics engineered for durability, comfort, and structural integrity, Acme Mills supported the client’s production of premium seating and interior components. This collaboration reinforces Acme Mills’ role as a trusted supplier of innovative material solutions for demanding manufacturing applications.