Precision Cutting, Endless Possibilities

Transform Your Materials with Our Expert Slitting and Rerolling Services

Fairway Products has been a leader in slitting and rerolling materials since 1951. Our parent company, Acme Mills, has over 100 years of experience in producing high-quality fabrics.

When you need slitting and rewinding, you can count on fast turnaround times and narrow width capabilities. We also have stocking options that can help you save time. Plus, by leveraging Acme Mills’ buying power, you can often get materials at better prices.

With our extensive network of suppliers, we can handle a wide range of materials, including woven fabrics, knits, paper, films, adhesives, and non-wovens. We offer specialized services like non-woven textile slitting services and paper and pulp roll slitting services to meet your exact needs.

Your product can be optimized and re-invented with our help.

The Power of Fairway

Unlock the full potential of your materials with precision slitting and rerolling. Whether you need narrow widths or high-quality custom products, we have the equipment and expertise to deliver. When you choose Fairway Products, you get high precision and efficiency for industries like automotive and filtration. You can also take advantage of our slitting services for adhesives and films, ensuring your materials are transformed to the highest standards. If you’re looking for high-performance filtration pads or needle-free fabric bonding, our services are designed to meet your needs and exceed expectations. Experience how Fairway Products can help elevate your manufacturing process.

Applications

Seat covers, headliners, carpets, insulation, sealing tapes

Crop covers, mulch films, geotextiles

Surgical drapes, gowns, masks, wound care products

Air filters, liquid filters, industrial filtration media

Features

Benefits

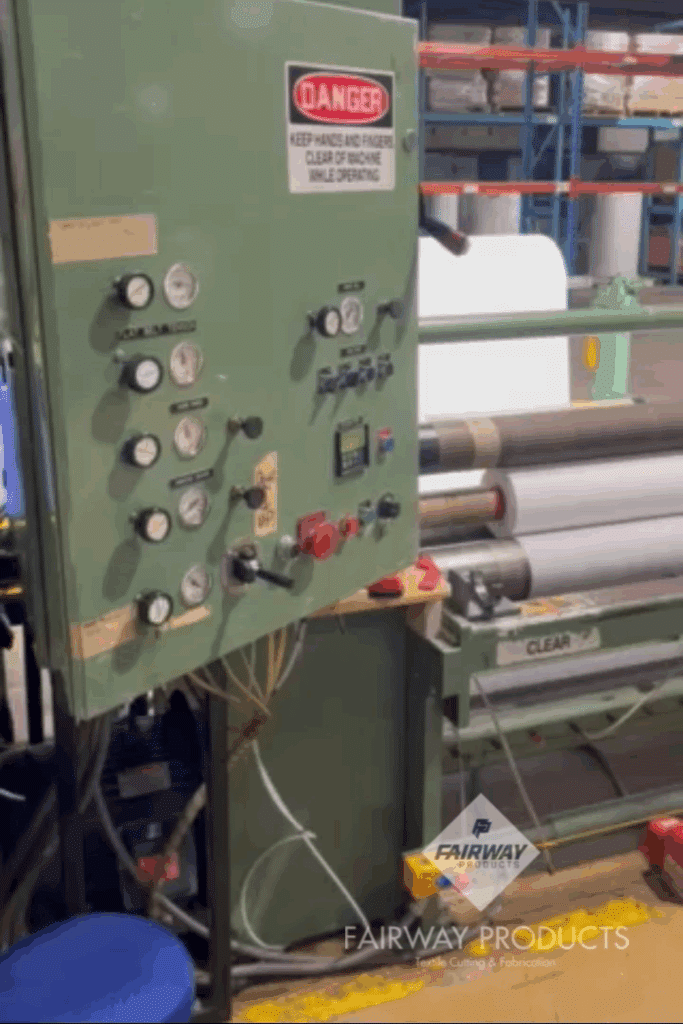

Key Equipment

Slitting and Rerolling Capabilities

Non-Wovens

Wovens

PAPer u0026amp; Advanced Material

Key Markets

Automotive

Aerospace

Textiles