Comprehensive Textile Sewing Solutions

Industrial Sewing, Product Development, and Nonwoven Filtration

Fairway Products’ industrial sewing capabilities provide us with a quality-oriented and cost-efficient background to manufacture products to our customers’ specifications. Along with our industrial sewing services, we can also provide product development and engineering skills to work with woven and non-woven fabrics, vinyl, foam, laminates, leather, and more. Our contract industrial sewing services can help you grow your ideas into a prototype, and we can support anything from small runs to mass production runs.

Because of their unusually high wet strength, light weight, good chemical resistance and low cost, nonwovens are outstanding for many filtering applications. We not only specialize in nonwovens for coolant filtration and offer a complete range of densities and micron ranges, but we are also able to cut and sew filter pouches, socks, tubes, and bags out of woven and nonwoven filter fabric.

An experience engineer can help you choose the optimal material, and our inhouse converting plants will ensure a quick turnaround and affordable pricing.

The Power of Fairway

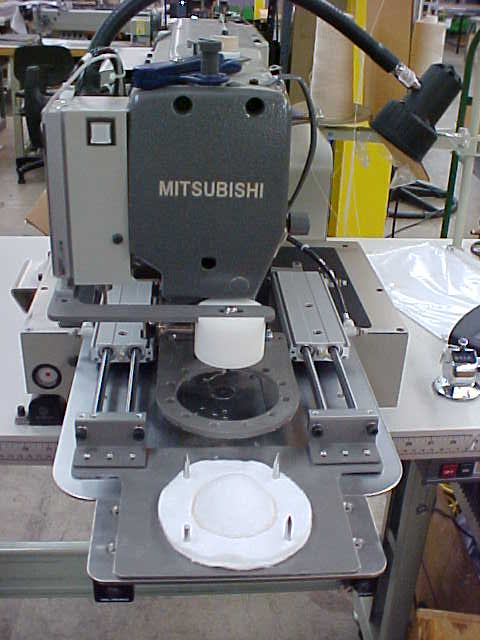

Fairway Products is committed to providing high-quality industrial sewing services that meet the rigorous standards of our diverse clientele. Our experienced team, state-of-the-art equipment, and dedication to excellence ensure that every project is completed to the highest specifications.

Applications

Seat covers, headrests, and other interior components.

Air filtration systems, Needle & Thread debris filters, Lint traps, vacuum systems, water filtration systems

Surgical covers, patient positioning devices, and protective gear.

Tarpaulins, storage bags, fabric covers,

storage covers, storage totes

Features

Benefits

Materials & Equipment

Specifications

Materials

Key Equipment

Key Markets

Automotive

Industrial Fabrics