As outlined in Google Patents under the entry “Technical Fabric and Welding Method of Seam Area, Using Ultrasonic Welding,” the invention focuses on using ultrasonic welding to enhance seam areas of technical fabrics. This advancement is particularly relevant in industries like papermaking, where technical fabrics play a critical role.

In the papermaking process, cellulosic fibrous webs are formed, pressed, and dried using specialized fabrics. These fabrics operate as endless loops, facilitating various stages like water removal, compression, and drying of the paper sheet. Manufacturers must customize these fabrics to fit specific paper machine configurations, which adds complexity to their production. Seam quality and durability are paramount to ensuring efficiency and reliability during this high-speed, continuous process.

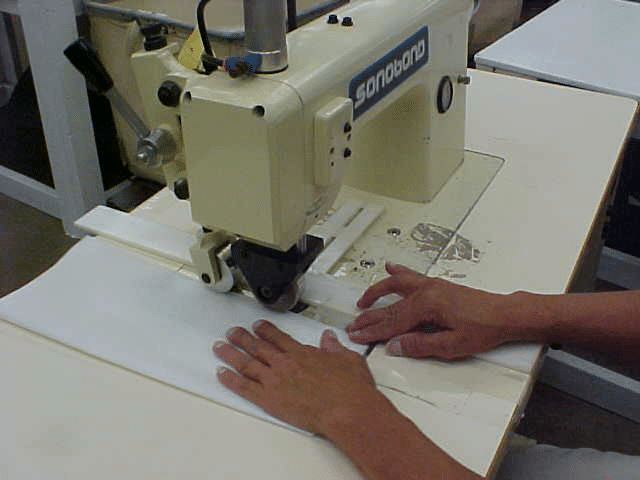

Ultrasonic welding presents a transformative solution for creating seamless, durable seams in technical fabrics. This method improves the strength and reliability of the seams without compromising the fabric’s structural integrity. It also aligns with the industry’s need for precision and high-performance materials tailored to the unique requirements of forming, pressing, and drying sections in paper machines.

Click here to learn more about Fairway Products’ capabilities and services.

Article with all rights reserved, courtesy of patents.google.com.