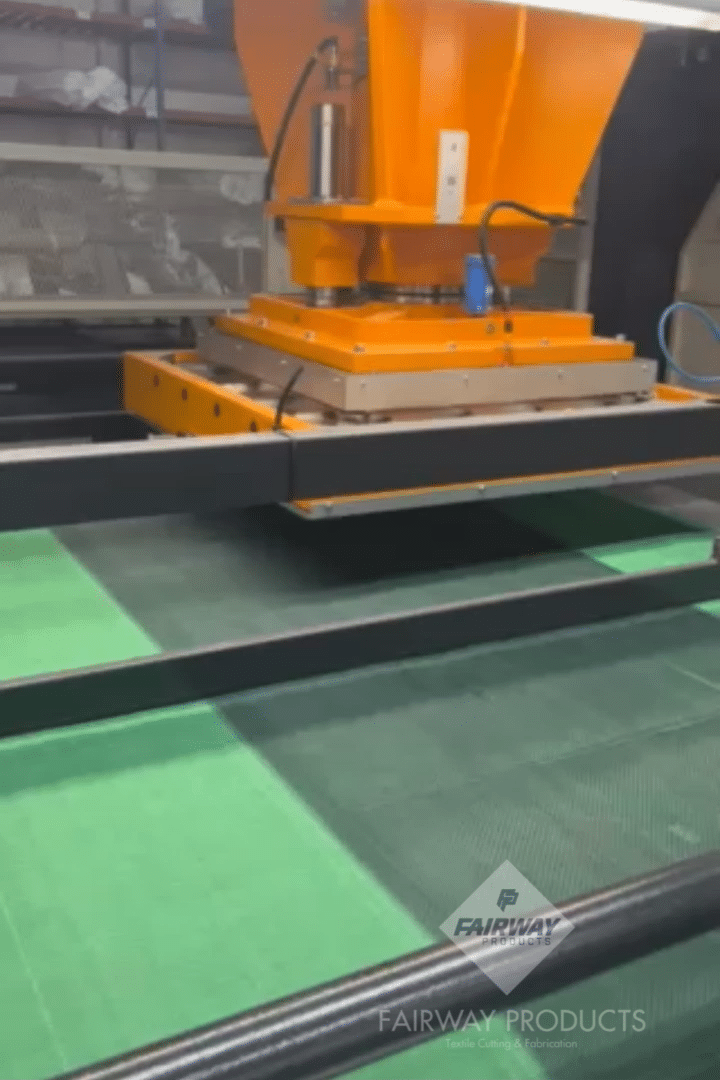

At Fairway Products, precision isn’t just a standard—it’s a commitment. For over six decades, we’ve specialized in industrial textile die cutting for a broad range of applications, from automotive interiors and filtration systems to medical components and outdoor gear. We understand that in today’s fast-paced manufacturing world, accuracy and efficiency are critical—and that’s exactly what we deliver.

Why Precision Matters

When you work with flexible materials like textiles, even a minor deviation can create a major problem. A product that’s off by just a few millimeters may not fit properly, function correctly, or meet compliance standards. That’s why our die cutting process is engineered to provide clean, repeatable cuts across a wide variety of technical fabrics and nonwovens.

Whether your project involves high-volume production or complex component shapes, our die cutting capabilities allow us to handle it with speed and precision—without compromising on quality.

Supporting a Range of Industries

Our clients come to us from diverse markets, and we tailor our solutions accordingly. We provide die-cut filter media for HVAC and industrial filtration systems, custom-shaped fabric pads for medical and hygiene applications, and padded components for seating and outdoor gear. Whatever your use case, our experienced team will work closely with you to develop a solution that meets both functional and cost objectives.

Efficiency Backed by Experience

With over 60 years of experience and a long-standing reputation for quality, we’ve refined our processes to reduce material waste and shorten production cycles. Our ability to integrate die cutting with services like contract sewing, sealing, and slitting means we offer an end-to-end manufacturing solution that saves our customers both time and money.

If you’re looking for a reliable partner who can bring precision and performance to your textile components, we’re ready to help.

Discover how Fairway Products delivers high-precision textile die cutting services for automotive, filtration, and medical industries with over 60 years of expertise.