Precision Slitting and Rerolling Services for All Textiles

At Fairway Products, precision is the cornerstone of our operations. Our Slitting and Rerolling Services are designed to provide exceptional material conversion solutions tailored to meet your specific needs. With decades of expertise and state-of-the-art technology, we ensure every roll of material is processed with meticulous attention to detail, delivering optimal results for a wide range of industries.

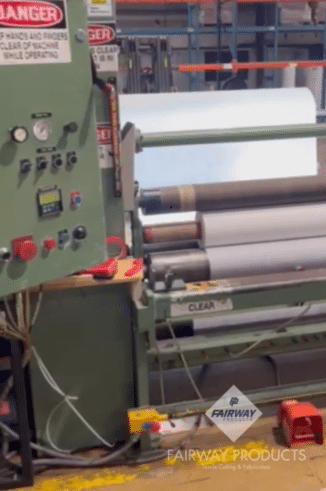

Cutting-Edge Technology for Every Material

We pride ourselves on offering solutions that accommodate a variety of materials, from woven fabrics and non-wovens to films, adhesives, and even specialty technical papers like chromatography and blotting paper. Our advanced equipment is equipped to handle diverse materials with tight tolerances, ensuring precision and quality every time.

Our capabilities include:

· 94 to 120-inch roll capacity for larger-scale projects.

· Tolerances as fine as ±1.5mm for exacting specifications.

· Variable blade packs, including serrated and straight blades, to handle different material types and thicknesses.

· Programmable yardage stops for consistent, repeatable outputs.

No matter the material, we have the expertise and equipment to deliver superior results.

Enhancing Your Production Efficiency

We understand that efficiency and consistency are vital to your operations. That’s why our slitting and rerolling solutions are engineered to optimize your production processes. Whether you require narrow-width slitting or large-scale rerolling, our team is committed to providing solutions that reduce downtime and material waste.

Our Cameron Slitters and Collins Drop Blade Cutters enable us to accommodate diverse requirements, including core sizes ranging from 1.5 to 8 inches. This versatility ensures that we can meet the needs of clients across industries, whether you’re in manufacturing, packaging, or filtration.

Tailored Solutions for Specialized Applications

At Fairway Products, we excel in handling complex projects and specialized materials. For instance, our expertise in slitting spunbond and meltblown fabrics makes us a trusted partner for filtration media providers. We also cater to industries requiring high-performance materials like nylon meshes, polyester blends, and layered composites.

Our team collaborates with you to understand your unique requirements, ensuring that every project is executed with precision and care. Learn more about our capabilities on our Slitting and Rerolling Services page and see how we can bring your material processing needs to life.