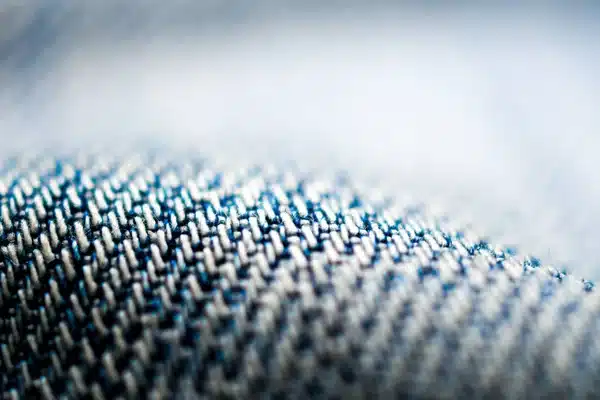

As reported by Lab Manager in their article “Cheaper Method for Making Woven Displays and Smart Fabrics,” researchers have developed a breakthrough in smart textile production. A team led by the University of Cambridge has found a way to produce smart fabrics—incorporating LEDs, sensors, and energy storage—using the same industrial looms that create everyday clothing. This approach is far more cost-effective and sustainable compared to traditional methods, which require expensive microelectronic fabrication facilities and produce significant waste.

The innovation marks a significant leap forward in the production of smart textiles, which were previously limited by manufacturing processes. The new method allows for flexible displays and smart fabrics to be created on an industrial scale without size or shape limitations. The research team demonstrated how various fiber devices, such as light-emitting diodes and energy storage units, can be woven into conventional textiles, offering exciting possibilities for industries such as automotive, fashion, and electronics.

One of the standout features of this approach is its durability. By coating the smart fibers with materials that can withstand stretching, bending, and folding, the team ensured the textiles could endure the rigorous conditions of industrial weaving machines. The fibers are interconnected using an automated laser welding technique, making the resulting smart fabrics not only durable but also scalable to larger dimensions.

This method holds immense potential for producing large, flexible displays, such as those used in automotive interiors, building materials, or even clothing, at a fraction of the cost typically associated with electronics manufacturing. Further optimization could lead to widespread adoption of this eco-friendly manufacturing platform, reducing carbon emissions and opening the door to more practical applications of smart textiles.

Click here to learn more about Acme Mills’ innovative solutions in textile manufacturing.

Article with all rights reserved, courtesy of labmanager.com.