In today’s fast-paced manufacturing landscape, businesses are constantly seeking innovative ways to improve product durability and operational efficiency. At Fairway Products, we recognize the pivotal role that advanced Seaming & Sealing techniques play in achieving these goals across various industries. From automotive and aerospace to medical and industrial applications, high-quality seams and seals are fundamental to ensuring superior product performance while optimizing costs and production timelines.

The Importance of Seaming & Sealing in Manufacturing

Effective Seaming & Sealing techniques are essential for creating durable, long-lasting products. Proper seams and seals not only enhance structural integrity but also improve resistance to environmental factors such as moisture, heat, and mechanical stress. Whether it’s sealing automotive upholstery, reinforcing medical protective gear, or strengthening industrial textiles, precision in seaming and sealing is non-negotiable.

One of the key advantages of utilizing advanced Seaming & Sealing techniques is the ability to enhance material longevity. By preventing fraying, leakage, or weakening of joints, our solutions contribute to improved wear resistance and extended product life cycles. This reliability is crucial for industries that demand high-performance materials, such as automotive and aerospace manufacturers that require strict compliance with safety and durability standards.

Cost-Effective Solutions for Modern Manufacturing

Beyond durability, our specialized Seaming & Sealing services also play a significant role in cost reduction. Properly sealed seams minimize material waste, reduce the need for secondary reinforcements, and enhance assembly line efficiency. Manufacturers can achieve significant savings by investing in high-quality seaming and sealing solutions that reduce production errors, rework, and material consumption.

Additionally, with the advent of automated and high-precision sealing technologies, we can ensure consistent and reliable seams that meet stringent quality control measures. This precision reduces downtime and speeds up production, ultimately improving turnaround times and increasing overall profitability.

Enhancing Efficiency and Reducing Production Time

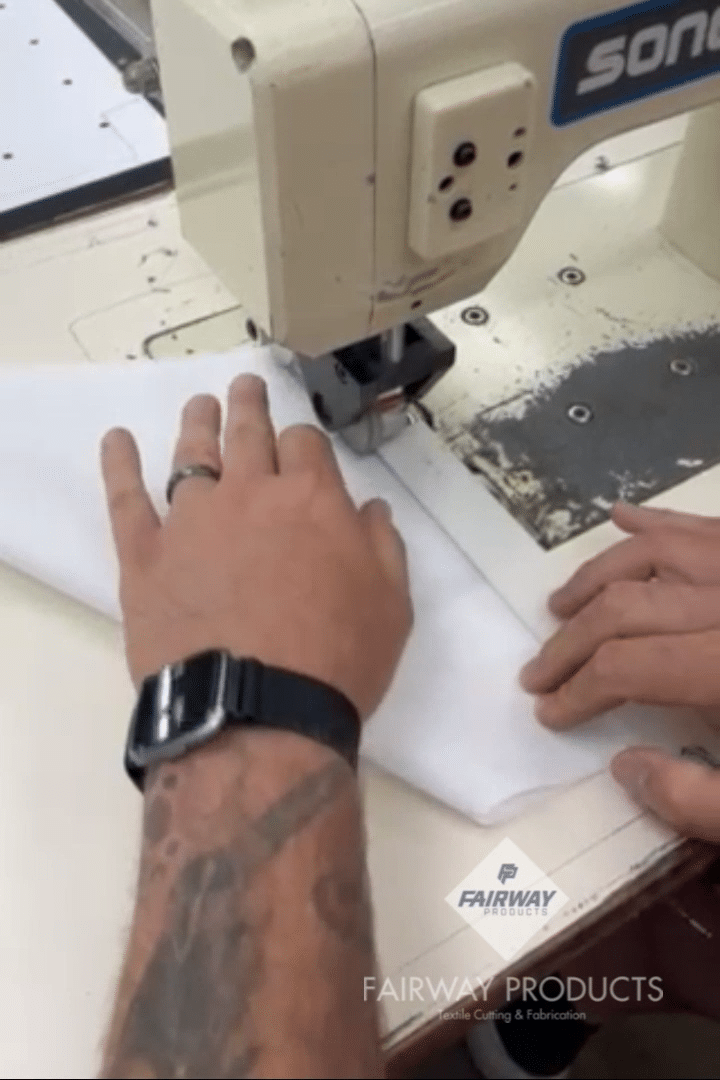

Efficiency in manufacturing is closely tied to streamlined production processes, and Seaming & Sealing plays a key role in optimizing workflow. Advanced sealing technologies enable rapid application, ensuring seamless integration with existing production lines. With techniques such as ultrasonic welding, heat sealing, and RF welding, we provide solutions that cater to diverse manufacturing needs, improving efficiency without compromising quality.

In industries such as medical textiles, where contamination control is paramount, our advanced Seaming & Sealing techniques ensure airtight and fluid-resistant seams that meet stringent health and safety regulations. This guarantees that critical protective gear, such as surgical gowns and medical drapes, maintain their integrity during use, enhancing safety for end-users.

Customized Seaming & Sealing for Diverse Applications

At Fairway Products, we understand that no two manufacturing processes are alike. That’s why we offer tailored Seaming & Sealing solutions to meet the specific requirements of various industries. Whether it’s high-strength seams for industrial applications, waterproof sealing for outdoor gear, or flame-resistant seals for aerospace components, our expertise ensures the perfect fit for your unique needs.

Our team of specialists works closely with manufacturers to determine the best sealing methods based on material composition, intended use, and performance expectations. By leveraging cutting-edge technologies and decades of industry expertise, we help businesses achieve superior product performance while maintaining cost-efficiency.

The Future of Seaming & Sealing in Manufacturing

As the demand for high-performance materials continues to rise, innovations in Seaming & Sealing will play an even more critical role in shaping the future of manufacturing. Advancements in automation, eco-friendly sealing materials, and smart textile integration will drive further improvements in durability, efficiency, and sustainability.

At Fairway Products, we remain committed to staying at the forefront of these technological advancements. By continuously refining our techniques and investing in state-of-the-art equipment, we ensure that our clients receive the most reliable, efficient, and cost-effective solutions available in the industry.

Conclusion

Incorporating advanced Seaming & Sealing techniques into modern manufacturing processes is essential for enhancing product durability, improving efficiency, and reducing costs. Whether in the automotive, medical, or industrial sectors, precision seaming and sealing provide a competitive edge by extending product life, minimizing waste, and ensuring compliance with industry standards.

At Fairway Products, we take pride in offering innovative solutions that meet the evolving needs of manufacturers. Contact us today to learn how our expertise in Seaming & Sealing can elevate your production process and deliver superior results.