At Fairway Products, we understand that in the world of textiles, precision isn’t a luxury—it’s a necessity. Whether it’s for automotive interiors, industrial filters, or high-performance seating, every detail counts. That’s why we’ve spent decades refining our Textile Die Cutting capabilities to help manufacturers across industries produce reliable, consistent, and exact-fit components at scale.

Why Precision Die Cutting Matters

Precision die cutting is more than just slicing fabric. It’s a complex, highly controlled process that requires accuracy to within fractions of a millimeter. Our clients demand uniformity and efficiency, and with our advanced cutting technology, we’re able to meet—and often exceed—those expectations.

Our process ensures that each piece we cut is consistent from the first to the last, regardless of material type. Whether we’re working with foam, felt, woven or non-woven textiles, the outcome is always dependable. This is especially critical in industries such as:

- Automotive, where components must meet exact fit and safety standards

- Filtration, where tolerances directly affect performance

- Medical and hygiene, where compliance and cleanliness are essential

- Furniture and seating, where repeatability ensures uniform assembly

Our Technology, Your Advantage

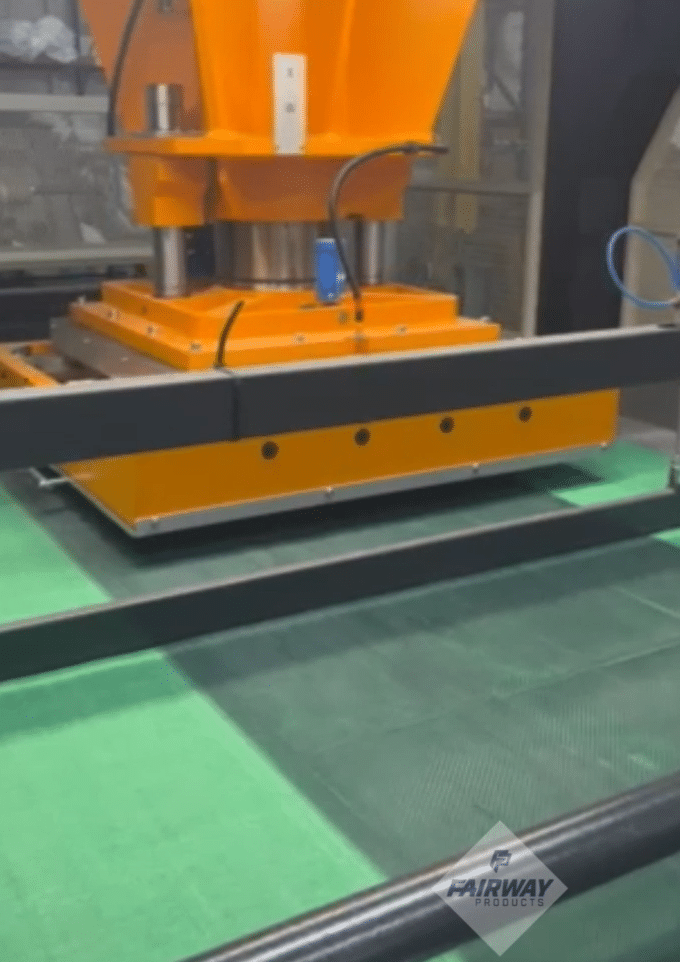

We use a variety of die cutting techniques depending on the project requirements. From flatbed to rotary die cutting, we choose the optimal process based on volume, material, and end-use application. Our machines are capable of cutting complex shapes, patterns, and configurations without compromising on speed or accuracy.

But what really sets us apart is our in-house engineering team. We don’t just take your designs and run them—we work collaboratively to refine patterns, minimize material waste, and enhance production efficiency. This partnership model helps us reduce your overall production costs while elevating quality.

Applications That Rely on Die Cutting

Our Textile Die Cutting services support a wide variety of products, including:

- Acoustic insulation panels

- HVAC filter frames

- Seat cushions and backrests

- Gaskets, spacers, and technical textile components

- Sanitary product liners

Because we operate with both short and long-run production capabilities, we serve clients ranging from startup manufacturers to global OEMs. Regardless of scale, our commitment to precision remains the same.

Customization and Consistency at Scale

One of the most critical aspects of textile die cutting is the ability to maintain tight tolerances over large production runs. At Fairway Products, we understand how even a slight deviation can impact the fit or function of a product. That’s why we invest in continuous calibration and quality control throughout the process.

We also offer value-added services such as adhesive lamination, multi-layer bonding, and product assembly. When you work with us, you’re not just getting cut fabric—you’re getting a complete, production-ready solution.

Why Choose Fairway?

Fairway Products brings more than six decades of experience to every project. We’re proud to serve industries that power our daily lives, and we take that responsibility seriously. With precision cutting, rapid prototyping, and scalable production, we help our clients bring better products to market faster.

So whether you’re launching a new product or improving an existing one, our Textile Die Cutting services offer the precision, speed, and flexibility your operation demands.