The article “Types of Filtration Equipment Used in the Chemical Industry” by Chemicals Learning provides insight into the essential role of filtration equipment across industries. Standing at the forefront of advancing filtration solutions, particularly in the chemical sector, it contributes to cleaner processes and product quality. Filtration equipment has become indispensable in various industries, ensuring clean drinking water and facilitating manufacturing processes. Specializing in providing innovative filtration solutions tailored to the needs of the chemical industry, it enhances efficiency and productivity.

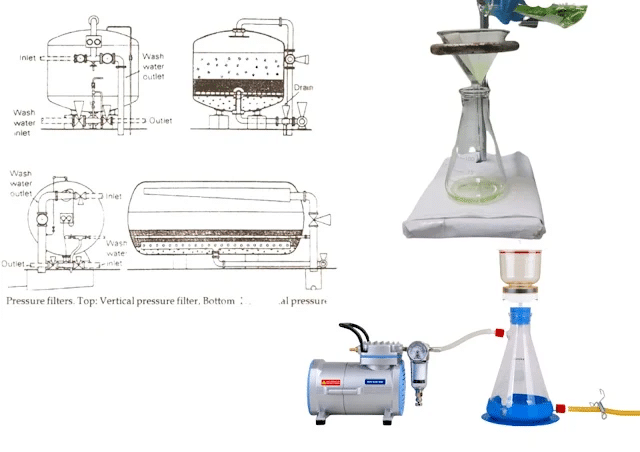

One of the primary types of filters used in chemical processes is cake filters, which retain visible quantities of filtered solids on the surface of the filter medium. This filtration method is crucial for removing impurities and ensuring product purity.

Additionally, clarifying filters play a vital role in producing clear liquids by removing small amounts of solids. Expertise in deep bed filtration ensures the removal of impurities, contributing to the quality of chemical products.

In terms of operating cycles, batch filters and continuous filters are widely used in the chemical industry. Batch filters, also known as filter presses, effectively remove solids from liquids through pressure filtration. Continuous filters, on the other hand, facilitate the separation of solids from liquids in a continuous flow process, ensuring consistent product quality.

The commitment to innovation and quality ensures that filtration equipment meets the rigorous demands of the chemical industry. By providing reliable and efficient filtration solutions, it contributes to the advancement of chemical processes and product quality.

Explore more about Great Lakes Filter’s filtration innovations here.

Photo and article with all rights reserved, courtesy of chemicalslearning.com.