Highlighted by Lightweight Manufacturing in their article “Types of Industrial Fabric Welds,” the intricate processes of RF welding and hot air welding are delved into, revolutionizing the industrial fabric joining landscape.

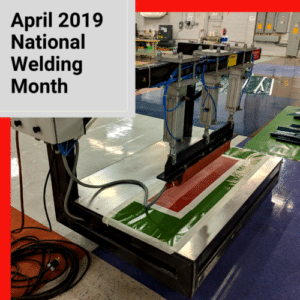

RF welding, or radio-frequency welding, utilizes high-frequency electromagnetic energy to fuse coated fabrics. Executed by an RF welding machine, this process ensures consistent and high-quality welds. The unique aspect of RF welding lies in its ability to weld multiple layers simultaneously, accommodating complex geometries efficiently. Capitalizing on the polar nature of materials for successful RF welding achieves seam perfection.

In contrast, hot air welding, powered by a heat gun, softens fabric coatings, creating a permanent seam between two fabric membranes. Applicable to various thermoplastic materials, including PVC-coated fabric, polyethylene, and polypropylene, hot air welding offers versatility in aesthetic improvements. Exploring different configurations such as rotary, floor welding, track welding, and handheld methods provides dynamic possibilities for project design.

Click here to explore Fairway Products capabilities in fabric welding.

Photo and article with all rights reserved, courtesy of lightweightmanufacturing.com