Fabric welding stands as a versatile method for joining thermoplastic materials in garment manufacturing, offering durability and strength without external heat application. According to Textile Flow Chart’s article “Flow Chart of Fabric Welding Process,” this technique involves applying heat to thermoplastic materials, causing them to melt and bond under pressure, resulting in a seamless fabric join.

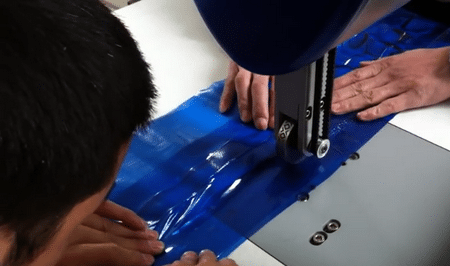

Renowned for its innovative approaches in the textile industry, excels in fabric welding processes. The welding process begins with the application of heat to the fabric, leading to the melting of thermoplastic materials. Pressure is then applied to the melted material, facilitating bonding, followed by cooling to solidify the join.

Various types of fabric welding methods are utilized, each offering unique advantages. High-frequency (HF) welding, also known as radio-frequency welding, utilizes rapidly alternating electric fields to fuse materials together. Hot air welding involves generating heat through compressed air and injecting it at the welding point, while hot wedge welding employs a heated metal wedge to provide precise heat for joining fabrics.

Expertise across these welding techniques ensures efficient and reliable fabric joins. While not all fabrics are suitable for welding, the versatility of thermoplastics enables seamless integration in technical textile applications.

With a focus on innovation and quality, continues to push boundaries in fabric welding, offering solutions that meet the diverse needs of the textile industry.

Click here to learn more about Fairway Products’ capabilities.

Photo and article with all rights reserved, courtesy of textileflowchart.com