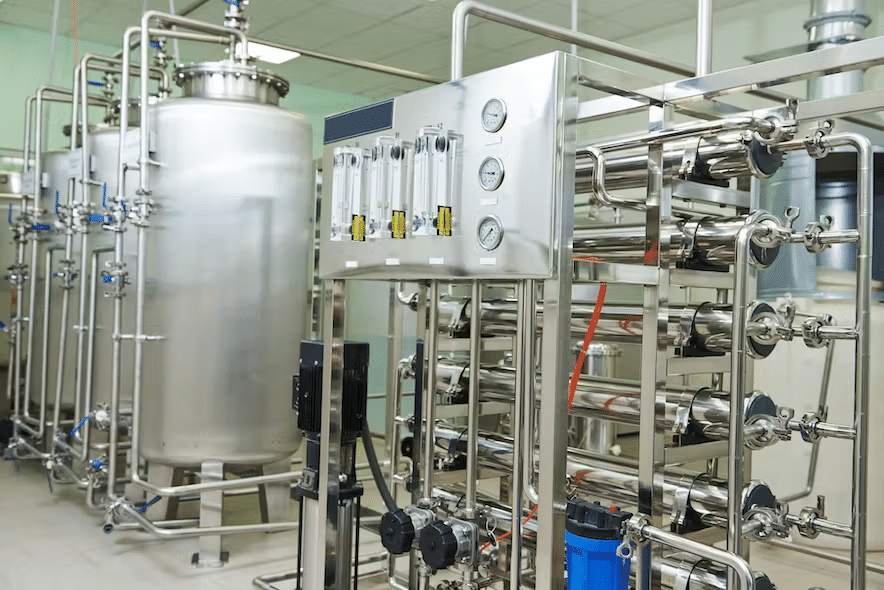

The article “Filter Types for the Pharmaceutical Industry,” sourced from Watertech Online, delves into the significant role of filters in ensuring purity within various industries. Filters act as crucial tools to capture and confine contaminants, enabling the passage of desired liquids. Particularly in the pharmaceutical sector, membrane filters play a vital role in sterilizing and deionizing water for subsequent industry use. The process of selecting an appropriate filter involves considering a range of factors.

Within the pharmaceutical realm, diverse filtration systems are prevalent. Surface filtration, depth filtration, and ultrafiltration are all utilized for distinct purposes, each bringing its own set of advantages. Here, we delve into key insights about each filtration system type.

Surface filtration systems are specifically designed to retain particles on the surface of the material undergoing filtration. Over time, these particles accumulate and create a solid layer known as a “cake layer.” This layer enhances the filter’s efficiency as it develops. Although the initial filtration rate with surface filters starts around 55 percent, it eventually escalates to 100 percent once the cake layer forms. However, the filtration flow will decrease over time due to particle buildup, necessitating periodic maintenance. Consequently, the system must be halted to facilitate filter cleaning.

Click here to learn more about Acme Mills products and services.

Photo and article with all rights reserved, courtesy of watertechonline.com