At Acme Mills, we pride ourselves on staying at the forefront of textile innovation, and our Contour – MDX brand is a testament to this commitment. As the demands of various industries evolve, so too must the materials we use to meet these challenges. Contour – MDX represents the cutting edge of 3D breather and spacer fabrics, offering a modern alternative to traditional materials like foam that are prone to degradation and environmental concerns.

What Sets Contour – MDX Apart

One of the most significant advantages of Contour – MDX fabrics is their ability to overcome the limitations of foam. Unlike foam, which can dry out, yellow, become heavy, and retain moisture, our 3D spacer fabrics maintain their integrity and performance over time. This makes them an ideal choice for applications where durability, breathability, and aesthetic appeal are paramount.

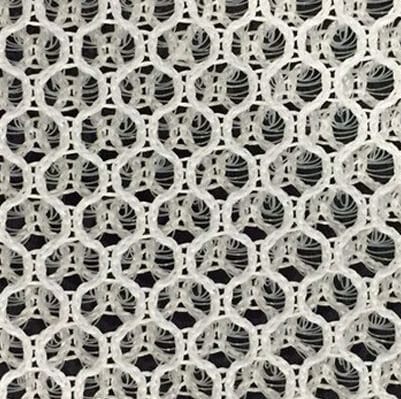

The Contour – MDX technology offers fire retardancy and ensures that the fabric won’t delaminate, which is critical in industries where safety is a top priority. The fabric’s unique construction allows for variable spacing between the two faces, ranging from 0.06 inches to over 0.5 inches (12 mm), depending on the specific needs of the application. This versatility is one of the key reasons why Contour – MDX has become a go-to solution for a wide range of industries.

The Benefits of 3D Spacer Fabrics

Our 3D spacer fabrics are engineered to provide superior breathability, which is essential in applications where air circulation and moisture management are critical. The design of these fabrics allows for varying elongation and stability of the yarns, offering a customized solution that meets the unique demands of each project.

One of the most exciting aspects of 3D spacer fabrics is the ability to design the appearance of both the top and bottom layers independently. This means that we can tailor the performance characteristics and aesthetic qualities of each layer to meet the specific needs of our clients. Whether it’s contract furniture that requires enhanced comfort and design flexibility or automotive interiors that demand durability and style, Contour – MDX fabrics provide the perfect solution.

Innovation Across Industries

At Acme Mills, we are constantly pushing the boundaries of what’s possible with our textile solutions. The versatility of Contour – MDX has led to its adoption across a wide range of industries, including automotive, furniture, medical, and more. Each of these sectors benefits from the unique properties of our 3D spacer fabrics, which are changing the way products are designed and manufactured.

For instance, in the contract furniture industry, Contour – MDX fabrics are revolutionizing the way seating is constructed. The enhanced breathability and comfort provided by our 3D spacer fabrics result in furniture that not only looks great but also offers superior performance over its lifespan. In the automotive sector, our fabrics contribute to the development of interiors that are both stylish and functional, withstanding the rigors of daily use while maintaining their aesthetic appeal.

Our Commitment to Quality and Innovation

As we continue to develop and refine our Contour – MDX offerings, our focus remains on providing our clients with the highest quality products that meet their specific needs. We work closely with our customers to understand their challenges and collaborate on creating solutions that deliver real value. Whether it’s enhancing the durability of a product, improving its aesthetic appeal, or meeting stringent safety standards, our Contour – MDX fabrics are designed to exceed expectations.

In conclusion, Contour – MDX represents the next generation of textile solutions, offering unmatched performance, versatility, and innovation. At Acme Mills, we are proud to lead the way in developing products that not only meet the demands of today’s industries but also set new standards for the future. We invite you to explore the potential of Contour – MDX and discover how our 3D spacer fabrics can transform your products and applications.