Article Options: The article “Ultrasonic Welding: A Promising Technology to Weld Both Plastics and Metals,” sourced from Interesting Engineering, delves into the realm of welding techniques as a means of joining materials. While techniques like fastening, stitching, and gluing have their merits, welding stands out for its unmatched results in creating strong and durable bonds.

The welding landscape encompasses various methods, each tailored to unique requirements and material types. Among the cutting-edge methods, ultrasonic welding has emerged as a modern and versatile approach. Ultrasonic welding capitalizes on ultrasonic vibration to unite diverse materials, even extending beyond metals to encompass thermoplastics.

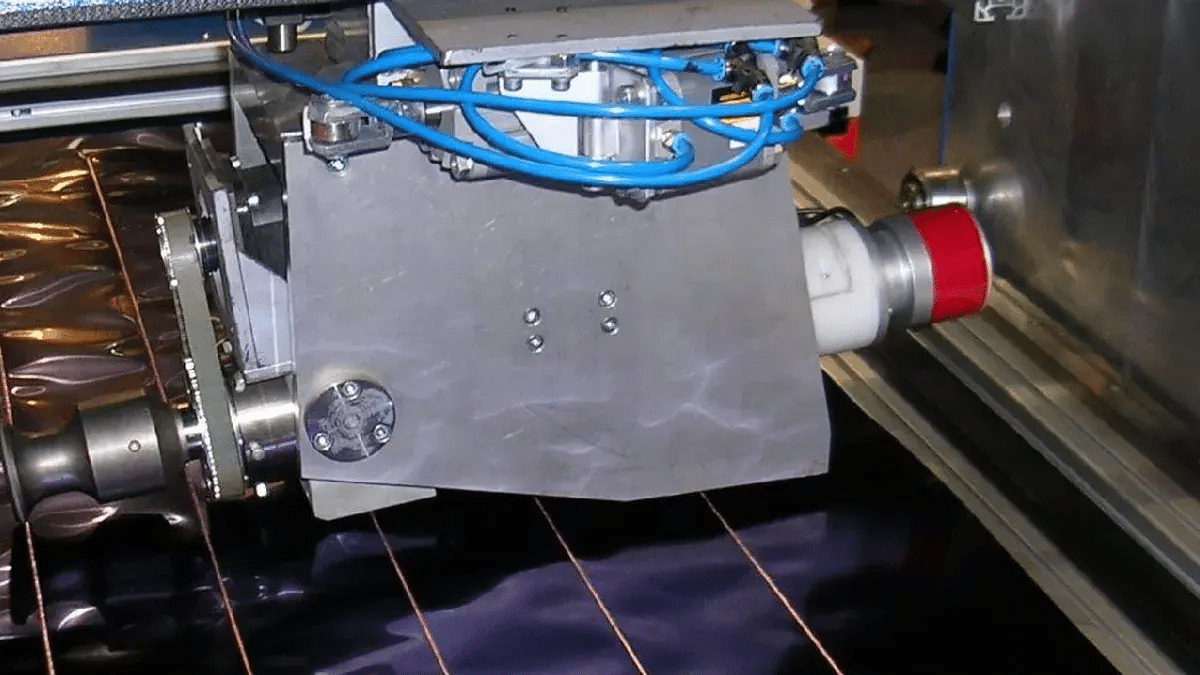

The essence of ultrasonic welding lies in the application of ultrasonic vibration at contact points, inducing material melting. Typically, ultrasonic welding operates within the frequency range of 15 to 40 kHz. This precision is attributed to the capability of ultrasonic welding equipment to focus vibration on localized spots, resulting in meticulous welds.

Components of ultrasonic welding systems encompass machines designed to efficiently convert electricity into mechanical vibrations. These machines are equipped with microprocessors for temperature monitoring and heating regulation.

Click here to learn more about Acme Mills products and services.

Photo and article with all rights reserved, courtesy of interestingengineering.com