Aircraft fabric coverings, like any other component, require maintenance and repairs over time. In the article “Polyester Fabric Repairs – Aircraft Fabric Covering,” we explore the world of aircraft fabric repairs, a crucial aspect of aviation safety.

Inspect and Identify: Before embarking on any repair, thorough inspection is key. Technicians must ensure that the damage is limited to the fabric and doesn’t involve the underlying structure. Identifying the approved data used during the initial covering installation is fundamental. This information can be found in the aircraft’s logbook, referencing manufacturer data, STCs (Supplemental Type Certificates), or field approvals, which may involve practices from AC 43.13-1. Importantly, the same source of approved data used for covering should guide the repair.

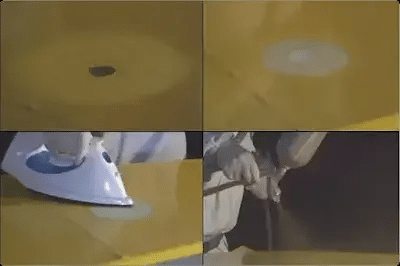

Repair Considerations: The nature of the repair depends on the extent of the damage and the fabric installation process. The size of the damaged area often dictates whether a patch or a new panel is required. It also influences the amount of fabric-to-fabric overlap needed for patching and the necessity of finishing tapes over the patch. It’s worth noting that many STC repair procedures may not necessitate finishing tapes, while some AC 43.13-1 repairs require tapes up to six inches wide.

Click here to learn more about Acme Mills products and services.

Photo and article with all rights reserved, courtesy of aircraftsystemstech.com