Enter the realm of ultrasonic welding, a technology that assembles products across diverse industries, from medical devices to athletic shoes to automobiles.

Traditionally, materials are bonded through methods like fasteners (nails, screws, thread) for metals, wood, fabrics, and plastics. Plastics often rely on glues to form chemical bonds between the glue and the plastic surfaces, while metals can be bonded through the application of heat, such as lead solder in electrical connections, or through direct melting (welding), which usually involves open flames or torches, making it costly for certain manufacturing processes.

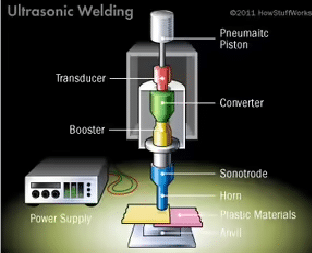

A more cost-effective welding technique emerged in the 1940s, introducing ultrasonic welding. This method utilizes high-frequency sound waves and pressure to bond metals together, requiring less energy than conventional welding. The evolution of ultrasonic metal welding continued through the 1950s to the 1990s, as advancements in electronics and computer control revolutionized the process. Today, ultrasonic welding has found widespread use in plastics manufacturing, where it has gained particular popularity.

Explore the science and application of ultrasonic welding further in this comprehensive article.

Click here to explore Acme Mills’ capabilities and products.

Photo and article with all rights reserved, courtesy of howstuffworks.com