Medical and Hygiene

Fairway Products: Ensuring Hygiene and Comfort in Medical Applications

Tailored Medical Products for Optimal Patient Care

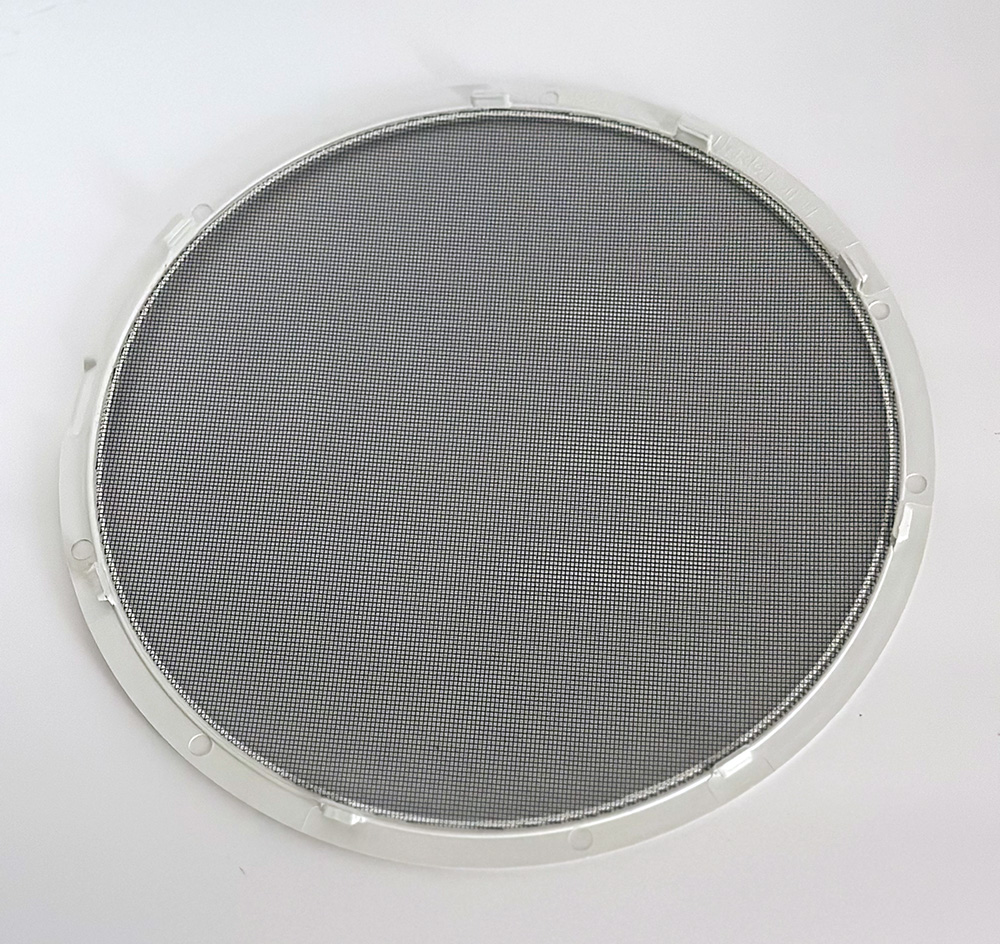

Fairway Products is committed to providing high-quality solutions that promote hygiene, comfort, and patient safety in various medical settings. Our diverse range of precision manufacturing processes are ideal for medical and hygiene products to ensure they meet the demanding needs of healthcare professionals to provide optimal patient care.

Explore Fairway Products’ Contributions to Medical and Hygiene Applications:

Key Equipment

Key Services

Industrial Textile Die Cutting

Utilizes advanced CNC machinery to cut filtration fabrics and materials with high precision.

Offers specialized sewing services for filtration products in commercial and industrial applications.

Provides comprehensive product development services for custom filtration solutions.

Specializes in seaming and sealing services to enhance the durability and functionality of filtration products.

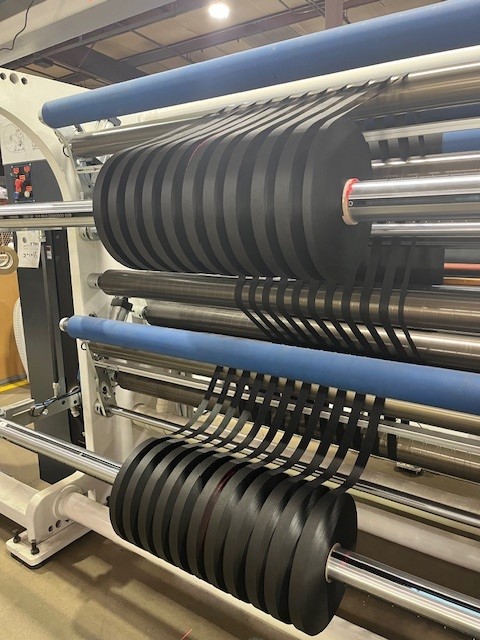

Industrial Slitting & Rerolling

Offers slitting and rerolling services to prepare filtration materials for further processing and production.

Fairway Products – Your Partner in Medical Excellence

We understand the critical role hygiene and comfort play in patient care. Fairway Products is dedicated to providing medical professionals with the reliable solutions they need to maintain a sterile environment, ensure patient well-being, and optimize workflow efficiency. Contact us today to discuss your specific medical and hygiene application needs and discover how Fairway Products can contribute to your success.