Industrial Manufacturing

Precision Cutting and Fabrication for Industrial Textiles

Tailored Solutions for Your Business

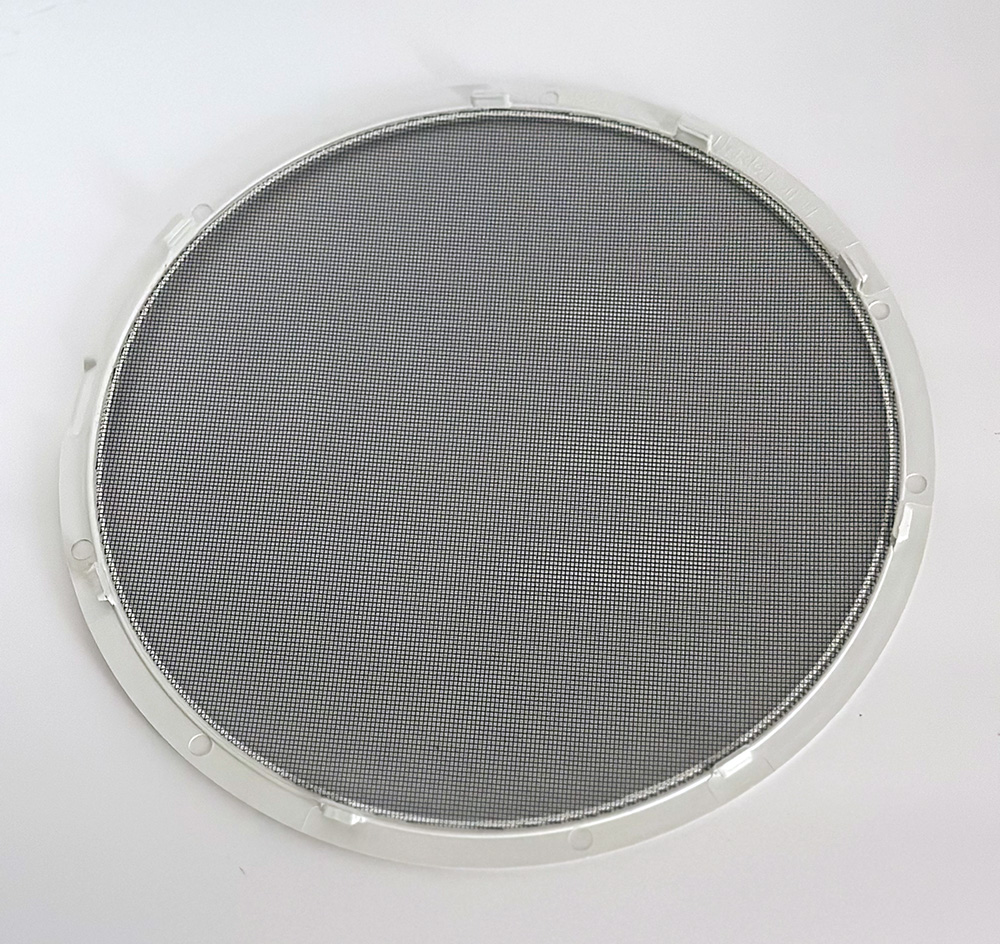

Fairway Products is your trusted partner for precision cutting and fabrication of industrial textiles. Our state-of-the-art equipment and skilled team deliver high-quality solutions tailored to your specific needs. From slitting nonwoven materials to assembling complex components, we handle every step of the process with precision and efficiency. Our expertise in a wide range of textile applications ensures that your products meet the highest industry standards.

Explore Fairway Products’ Contributions to Industrial Manufacturing Applications:

Key Equipment

Key Services

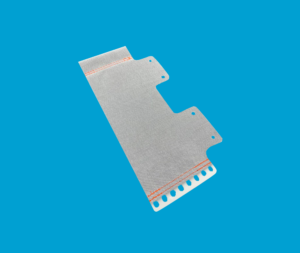

Industrial Textile Die Cutting

Utilizes advanced CNC machinery to cut fabrics and materials with high precision.

Offers specialized sewing services for commercial and industrial applications.

Offers specialized seaming and sealing services to enhance the durability and functionality of industrial textile products.

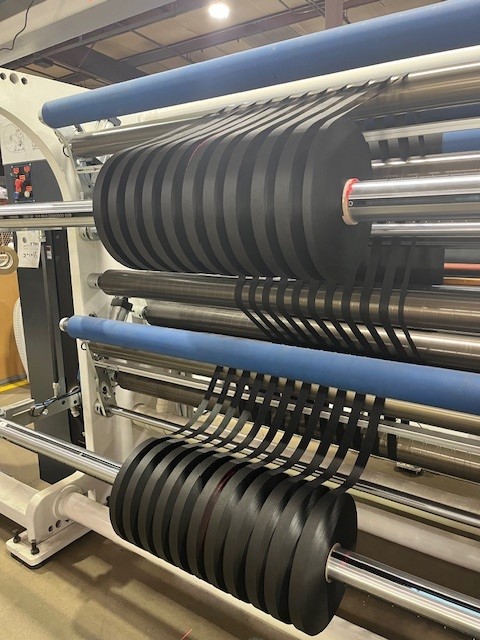

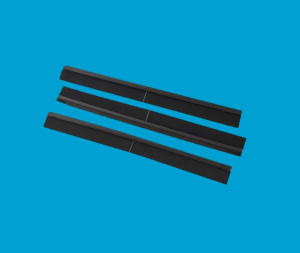

Industrial Slitting & Rerolling

Provides slitting and rerolling services to prepare materials for further processing and production.

Transform Your Ideas into Reality. Contact Us Today!

By leveraging our advanced equipment and specialized services, Fairway Products ensures the production of high-quality, durable, and functionally superior industrial textile products that meet the rigorous standards of our clients. Contact us today to get started.