Nonwoven fabric is a fabric-like material made from staple fiber (short) and long fiber (continuous long), bonded together by chemical, mechanical, heat or solvent treatment. The term is used in the textile manufacturing industry to denote fabrics, such as felt, which are neither woven nor knitted.

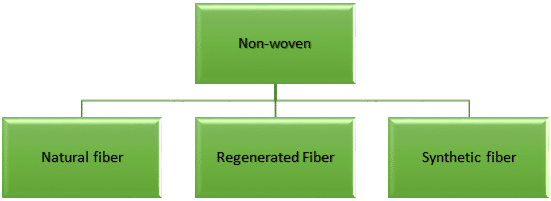

Different types of non-woven fabrics over-view

The non-woven fabrics can be divided into 8 types according to different manufacturing processes:

Spunlace nonwovens

It is a non-woven cloth, it is the direct use of polymer slices, short fibers or filaments into a network of fiber by air or mechanical, spunlace, acupuncture, or hot-rolled reinforcement, and finally after finishing the formation of spunlace nonwoven fabric.

Application: It is well-known for its great uses for facial mask fabric, medical non-woven fabric, wet wipe fabric, non-woven filter fabric and etc.

Heat-bonded nonwoven fabrics

This type of non-woven fabric is mainly manufactured in several processes: adding fibrous or sticky reinforcement material into the fiber network, and then reinforcing the network into cloth via heating and cooling.

Pulp air-laid nonwovens

Air-laid nonwovens can also be called the dustless paper or dry paper nonwovens. It uses the air-laid technology to open the wood pulp fiberboard into a single fiber state, then uses the airflow method to make the fiber agglomerate on the net curtain, and then consolidates the fiber web into cloth.

Wet-laid non-woven

The manufacturing process of wet nonwoven fabric goes like this: open the fibrous raw material in the aqueous medium into single fibers, meanwhile forming a fibrous suspension slurry by mixing different fiber raw materials, then transport the suspended slurry to a mesh-forming mechanism, and the fibers are laid in a wet state to form a cloth.

Spunbond nonwovens

Spunbond-type of nonwoven fabric is processed as follows: extrude and stretch the polymer to form a continuous filament, laid the filament into web, then process the web into nonwoven fabric through their own bonding, thermal bonding, chemical bonding or mechanical reinforcement methods.

Read more: Types of non-woven fabric, manufacturing processes and applications