The British Textile Industry

The British textile industry drove the Industrial Revolution, triggering advancements in technology, stimulating the coal and iron industries, boosting raw material imports, and improving transportation, which made Britain the global leader of industrialization, trade, and scientific innovation.

Pre-Industrial Textile Industry

Before the 17th century, the manufacture of goods was performed on a limited scale by individual workers, usually on their own premises. Goods were transported around the country by clothiers who visited the village with their trains of packhorses. Some was made into clothes for people living in the same area and a large amount was exported. In the early 18th century, artisans were inventing ways to become more productive. Silk, wool, fustian

(a cloth with flax warp and cotton weft), and linen were eclipsed by cotton, which was becoming the most important textile. This set the foundation for the changes.

In the early 18th century, the British government passed two Calico Acts to protect the domestic wool industry from the increasing amounts of cotton fabric imported from its competitors in India. On the eve of the Industrial Revolution, spinning and weaving were still done in households, for domestic consumption, and as a cottage industry under the putting-out system. Occasionally the work was done in the workshop of a master weaver. Under the putting-out system, home-based workers produced under contract to merchant sellers, who often supplied the raw materials. In the off season the women, typically farmers’ wives, did the spinning and the men did the weaving. Using the spinning wheel, it took anywhere from four to eight spinners to supply one hand loom weaver.

The key British industry at the beginning of the 18th century was the production of textiles made with wool from the large sheep-farming areas in the Midlands and across the country (created as a result of land-clearance and enclosure). This was a labor-intensive activity providing employment throughout Britain, with major centers in the West Country, Norwich and environs, and the West Riding of Yorkshire. The export trade in woolen goods accounted for more than a quarter of British exports during most of the 18th century, doubling between 1701 and 1770. Exports by the cotton industry – centered in Lancashire – grew tenfold during this time, but still accounted for only a tenth of the value of the woolen trade.

Industrial Revolution and Textiles

Starting in the later part of the 18th century, there was a transition in parts of Great Britain’s previously manual labor and draft animal-based economy toward machine-based manufacturing. It started with the mechanization of the textile industries, the development of iron-making techniques, and the increased use of refined coal. Trade expansion was enabled by the introduction of canals, improved roads, and railways. Factories pulled thousands from low-productivity work in agriculture to high-productivity urban jobs.

Textiles have been identified as the catalyst of technological changes and thus their importance during the Industrial Revolution cannot be overstated. The application of steam power stimulated the demand for coal. The demand for machinery and rails stimulated the iron industry. The demand for transportation to move raw material in and finished products out stimulated the growth of the canal system, and (after 1830) the railway system. The introduction of steam power fueled primarily by coal, wider utilization of water wheels, and powered machinery in textile manufacturing underpinned the dramatic increases in production capacity. The development of all-metal machine tools in the first two decades of the 19th century facilitated the manufacture of more production machines for manufacturing in other industries. The effects spread throughout Western Europe and North America during the 19th century, eventually affecting most of the world.

The invention of the flying shuttle by John Kay enabled wider cloth to be woven faster, but also created a demand for yarn that could not be fulfilled. Thus, the major technological advances associated with the Industrial Revolution were concerned with spinning. James Hargreaves created the spinning jenny, a device that could perform the work of a number of spinning wheels. However, while this invention could be operated by hand, the water frame, invented by Richard Arkwright, could be powered by a water wheel. Arkwright is credited with the widespread introduction of the factory system in Britain and is the first example of the successful mill owner and industrialist in British history. The water frame was, however, soon supplanted by the spinning mule (a cross between a water frame and a jenny) invented by Samuel Crompton. Mules were later constructed in iron.

In a period loosely dated from the 1770s to the 1820s, Britain experienced an accelerated process of economic change that transformed a largely agrarian economy into the world’s first industrial economy. The changes were far-reaching and permanent throughout many areas of Britain, eventually affecting the entire world.

The steam engine was invented and became a power supply that soon surpassed waterfalls and horsepower. The first practicable steam engine was invented by Thomas Newcomen and was used for pumping water out of mines. A much more powerful steam engine was invented by James Watt. It had a reciprocating engine capable of powering machinery. The first steam-driven textile mills began to appear in the last quarter of the 18th century, greatly contributing to the appearance and rapid growth of industrial towns.

The progress of the textile trade soon outstripped the original supplies of raw materials. By the turn of the 19th century, imported American cotton had replaced wool in the North West of England, although wool remained the chief textile in Yorkshire.

Such an unprecedented degree of economic growth was not sustained by domestic demand alone. The application of technology and the factory system created the levels of mass production and cost efficiency that enabled British manufacturers to export inexpensive cloth and other items worldwide. Britain’s position as the world’s preeminent trader helped fund research and experimentation. Further, some have stressed the importance of natural or financial resources that Britain received from its many overseas colonies or that profits from the British slave trade between Africa and the Caribbean helped fuel industrial investment.

Global Leader

After 1840, Britain abandoned mercantilism and committed its economy to free trade with few barriers or tariffs. This was most evident in the repeal in 1846 of the Corn Laws, which imposed stiff tariffs on imported grain. The end of these laws opened the British market to unfettered competition, grain prices fell, and food became more plentiful.

From 1815 to 1870 Britain reaped the benefits of being the world’s first modern, industrialized nation. The British readily described their country as “the workshop of the world,” meaning that its finished goods were produced so efficiently and cheaply that they could often undersell comparable locally manufactured goods in almost any other market. If political conditions in a particular overseas market were stable enough, Britain could dominate its economy through free trade alone without resorting to formal rule or mercantilism. By 1820, 30% of Britain’s exports went to its Empire, rising slowly to 35% by 1910. Apart from coal and iron, most raw materials had to be imported so in the 1830s, the main imports were (in order): raw cotton (from the American South), sugar (from the West Indies), wool, silk, tea (from China), timber (from Canada), wine, flax, hides, and tallow. By 1900, Britain’s global share soared to 22.8% of total imports. By 1922, its global share soared to 14.9% of total exports and 28.8% of manufactured exports.

Technological Developments in Textiles

The British textile industry triggered tremendous scientific innovation, resulting in such key inventions as the flying shuttle, spinning jenny, water frame, and spinning mule. These greatly improved productivity and drove further technological advancements that turned textiles into a fully mechanized industry.

Early Developments

During the second half of the 17th century, the newly established factories of the East India Company in South Asia started to produce finished cotton goods in quantity for the UK market. The imported calico and chintz garments competed with and acted as a substitute for indigenous wool and linen produce. That resulted in local weavers, spinners, dyers, shepherds, and farmers petitioning the Parliament to request a ban on the import and later the sale of woven cotton goods. They eventually achieved their goal via the 1700 and 1721 Calico Acts. The acts banned the import and later the sale of finished pure cotton produce, but did not restrict the importation of raw cotton or the sale or production of fustian

(a cloth with flax warp and cotton weft).

The exemption of raw cotton from the 1721 Calico Act saw 2,000 bales of cotton imported annually from Asia and the Americas and forming the basis of a new indigenous industry, initially producing fustian for the domestic market. More importantly, though, it triggered the development of a series of mechanized spinning and weaving technologies to process the material. This mechanized production was concentrated in new cotton mills, which slowly expanded. By the beginning of the 1770s, 7,000 bales of cotton were imported annually. The new mill owners put pressure on Parliament to remove the prohibition on the production and sale of pure cotton cloth as they could now compete with imported cotton.

Since much of the imported cotton came from New England, ports on the west coast of Britain such as Liverpool, Bristol, and Glasgow were crucial to determining the sites of the cotton industry. Lancashire became a center for the nascent cotton industry because the damp climate was better for spinning the yarn. As the cotton thread was not strong enough to use as warp, wool, linen, or fustian had to be used and Lancashire was an existing wool center.

Key Inventions

The textile industry drove groundbreaking scientific innovations. The flying shuttle was patented in 1733 by John Kay and saw a number of subsequent improvements including an important one in 1747 that doubled the output of a weaver It became widely used around Lancashire after 1760 when John’s son, Robert, designed a method for deploying multiple shuttles simultaneously, enabling the use of wefts of more than one color and making it easier for the weaver to produce cross-striped material. These shuttles were housed at the side of the loom in what became known as the drop box. Lewis Paul patented the roller spinning frame and the flyer-and-bobbin system for drawing wool to a more even thickness. The technology was developed with the help of John Wyatt of Birmingham. Paul and Wyatt opened a mill in Birmingham, which used their new rolling machine powered by a donkey. In 1743, a factory opened in Northampton with 50 spindles on each of five of Paul and Wyatt’s machines. It operated until about 1764. A similar mill was built by Daniel Bourn in Leominster, but it burnt down. Both Paul and Bourn patented carding machines in 1748. Based on two sets of rollers that traveled at different speeds, these were later used in the first cotton spinning mill. Lewis’s invention was advanced and improved by Richard Arkwright in his water frame and Samuel Crompton in his spinning mule.

In 1764 in the village of Stanhill, Lancashire, James Hargreaves invented the spinning jenny, which he patented in 1770. It was the first practical spinning frame with multiple spindles. The jenny worked in a similar manner to the spinning wheel by first clamping down on the fibers then drawing them out, followed by twisting. It was a simple, wooden-framed machine that cost only about £6 for a 40-spindle model in 1792 and was used mainly by home spinners. The jenny produced a lightly twisted yarn only suitable for weft, not warp.

The device reduced the amount of work needed to produce yarn, with a worker able to work eight or more spools at once. This grew to 120 as technology advanced.

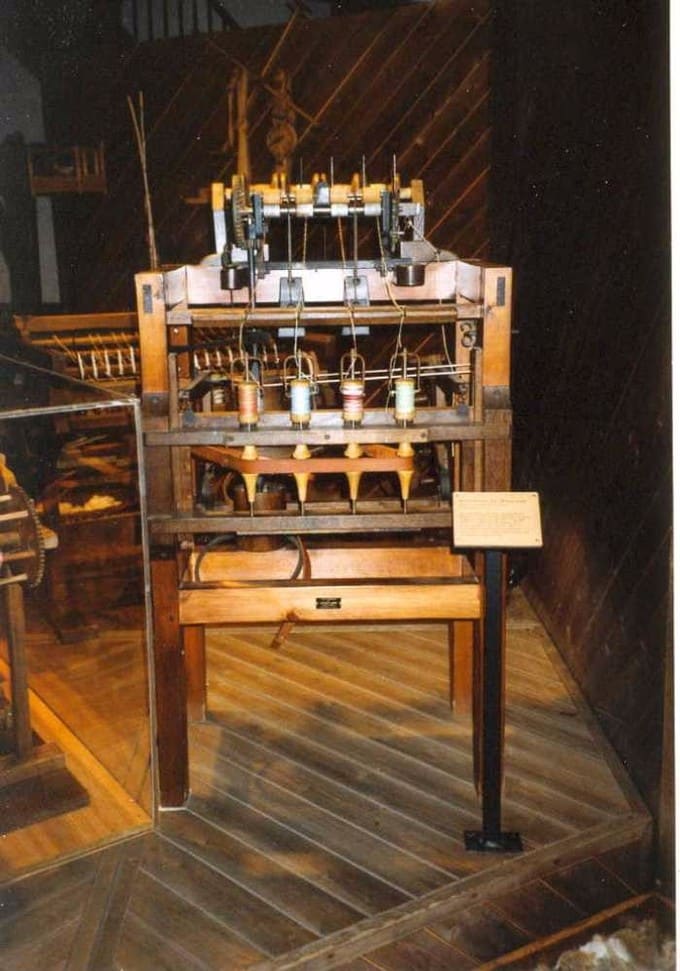

The spinning frame or water frame was developed by Richard Arkwright who along with two partners patented it in 1769. The design was partly based on a spinning machine built for Thomas High by clock maker John Kay, who was hired by Arkwright. For each spindle, the water frame used a series of four pairs of rollers, each operating at a successively higher rotating speed to draw out the fiber, which was then twisted by the spindle. The roller spacing was slightly longer than the fiber length. Closer spacing caused the fibers to break while further spacing caused uneven thread. The top rollers were leather-covered and loading on them was applied by a weight that kept the twist from backing up before the rollers. The bottom rollers were wood and metal, with fluting along the length. The water frame was able to produce a hard, medium count thread suitable for warp, finally allowing 100% cotton cloth to be made in Britain. A horse powered the first factory to use the spinning frame. Arkwright and his partners used water power at a factory in Cromford, Derbyshire in 1771, giving the invention its name.

Model of a water frame in the Historical Museum in Wuppertal

Richard Arkwright is credited with a list of inventions, but these were actually developed by such people as Thomas Highs and John Kay. Arkwright nurtured the inventors, patented the ideas, financed the initiatives, and protected the machines. He created the cotton mill, which brought the production processes together in a factory, and he developed the use of power—first horse power and then water power—which made cotton manufacture a mechanized industry.

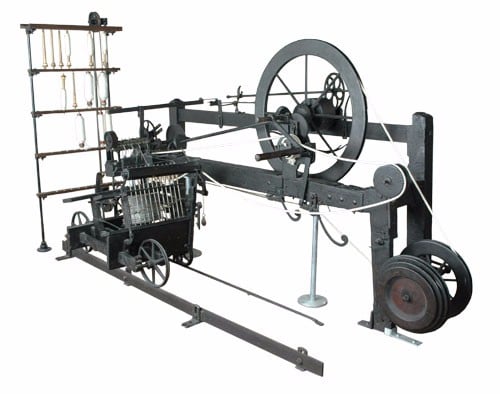

Samuel Crompton’s spinning mule, introduced in 1779, was a combination of the spinning jenny and the water frame. The spindles were placed on a carriage that went through an operational sequence during which the rollers stopped while the carriage moved away from the drawing roller to finish drawing out the fibers as the spindles started rotating. Crompton’s mule was able to produce finer thread than hand spinning at a lower cost. Mule spun thread was of suitable strength to be used as warp and finally allowed Britain to produce good-quality calico cloth.

The only surviving example of a spinning mule built by the inventor Samuel Crompton

The spinning mule spins textile fibers into yarn by an intermittent process. In the draw stroke, the roving is pulled through rollers and twisted. On the return it is wrapped onto the spindle.

Realizing that the expiration of the Arkwright patent would greatly increase the supply of spun cotton and lead to a shortage of weavers, Edmund Cartwright developed a vertical power loom which he patented in 1785. Cartwright’s loom design had several flaws, including thread breakage. Samuel Horrocks patented a fairly successful loom in 1813; it was improved by Richard Roberts in 1822, and these were produced in large numbers by Roberts, Hill & Co.

The textile industry was also to benefit from other developments of the period. As early as 1691, Thomas Savery made a vacuum steam engine. His design, which was unsafe, was improved by Thomas Newcomen in 1698. In 1765, James Watt further modified Newcomen’s engine to design an external condenser steam engine. Watt continued to make improvements on his design, producing a separate condenser engine in 1774 and a rotating separate condensing engine in 1781. Watt formed a partnership with a businessman Matthew Boulton and together they manufactured steam engines that could be used by industry.

Mechanization of the Textile Industry

With Cartwright’s loom, the spinning mule, and Boulton and Watt’s steam engine, the pieces were in place to build a mechanized textile industry. From this point there were no new inventions, but a continuous improvement in technology as the mill-owner strove to reduce cost and improve quality. Developments in the transport infrastructure such as the canals and, after 1830, the railways, facilitated the import of raw materials and export of finished cloth.

The use of water power to drive mills was supplemented by steam-driven water pumps and then superseded completely by the steam engines. For example, Samuel Greg joined his uncle’s firm of textile merchants and on taking over the company in 1782, sought out a site to establish a mill. Quarry Bank Mill was built on the River Bollin at Styal in Cheshire. It was initially powered by a water wheel, but installed steam engines in 1810. In 1830, the average power of a mill engine was 48 horsepower (hp), but Quarry Bank mill installed an new 100 hp water wheel. This would change in 1836, when Horrocks & Nuttall, Preston took delivery of 160 hp double engine. William Fairbairn addressed the problem of line-shafting and was responsible for improving the efficiency of the mill. In 1815, he replaced the wooden turning shafts that drove the machines to wrought iron shafting, which were a third of the weight and absorbed less power. The mill operated until 1959.

In 1830, using an 1822 patent, Richard Roberts manufactured the first loom with a cast-iron frame, the Roberts Loom. In 1842, James Bullough and William Kenworthy made a semiautomatic power loom known as the Lancashire Loom. Although it was self-acting, it had to be stopped to recharge empty shuttles. It was the mainstay of the Lancashire cotton industry for a century, when the Northrop Loom invented in 1894 with an automatic weft replenishment function gained ascendancy.

The 1824 Stalybridge mule spinners strike stimulated research into the problem of applying power to the winding stroke of the mule. In 1830, Richard Roberts patented the first self-acting mule. The draw while spinning had been assisted by power, but the push of the wind was done manually by the spinner. Before 1830, the spinner would operate a partially powered mule with a maximum of 400 spindles. After 1830, self-acting mules with up to 1,300 spindles could be built. The savings with this technology were considerable. A worker spinning cotton at a hand-powered spinning wheel in the 18th century would take more than 50,000 hours to spin 100 pounds of cotton. By the 1790s, the same quantity could be spun in 300 hours by mule, and with a self-acting mule it could be spun by one worker in just 135 hours.

Export Technology

While profiting from expertise arriving from overseas, Britain was very protective of home-grown technology. In particular, engineers with skills in constructing the textile mills and machinery were not permitted to emigrate — particularly to the fledgling America. However, Samuel Slater, an engineer who had worked as an apprentice to Arkwright’s partner Jedediah Strutt, evaded the ban. In 1789, he took his skills in designing and constructing factories to New England and was soon engaged in reproducing the textile mills that helped America with its own industrial revolution. Local inventions followed. In 1793, Eli Whitney invented and patented the cotton gin, which sped up the processing of raw cotton by over 50 times. With a cotton gin a man could remove seed from as much upland cotton in one day as would have previously taken a woman working two months to process

at one pound per day.

The First Factories

The factory system was a new way of organizing labor made necessary by the development of machines, which were too large to house in a worker’s cottage and too expensive to be owned by the worker, who now labored long hours and lived under hazardous conditions in fledgling cities.

Rise of the Factory System

Prior to the Industrial Revolution, most of the workforce was employed in agriculture, either as self-employed farmers as land owners or tenants, or as landless agricultural laborers. By the time of the Industrial Revolution the putting-out system in which farmers and townspeople produced goods in their homes, often described as cottage industry, was the standard. Typical putting-out system goods included spinning and weaving. Merchant capitalists provided the raw materials, typically paid workers by the piece, and were responsible for the sale of the goods. Workers put long hours into low-productivity but labor-intensive tasks. The logistical effort in procuring and distributing raw materials and picking up finished goods were also limitations of the system.

Some early spinning and weaving machinery, such as a 40 spindle spinning jenny for about six pounds in 1792, was affordable to cottagers. Later machinery such as spinning frames, spinning mules, and power looms were expensive (especially if water-powered), giving rise to capitalist ownership of factories. Many workers, who had nothing but their labor to sell, became factory workers in the absence of any other opportunities.

The factory system was a new way of organizing labor made necessary by the development of machines, which were too large to house in a worker’s cottage and much too expensive to be owned by the worker. One of the earliest factories was John Lombe’s water-powered silk mill at Derby, operational by 1721. By 1746, an integrated brass mill was working at Warmley near Bristol. Raw material went in at one end, then smelted into brass to become pans, pins, wire, and other goods. Housing was provided for workers on site. Josiah Wedgwood in Staffordshire and Matthew Boulton at his Soho Manufactory were other prominent early industrialists, who employed the factory system. However, Richard Arkwright is credited as the brains behind the growth of factories and, specifically, the Derwent Valley Mills. After he patented his water frame in 1769, he established Cromford Mill in Derbyshire, England.

The Soho Manufactory, J. Bissett’s Magnificent Directory, 1800.

This early factory was established by the toy manufacturer Matthew Boulton and his business partner John Fothergill. In 1761, they leased a site on Handsworth Heath, containing a cottage and a water-driven metal-rolling mill. The mill was replaced by a new factory, designed and built by the Wyatt family of Lichfield, and completed in 1766. It produced a wide range of goods from buttons, buckles, and boxes to japanned ware (collectively called “toys”) and later luxury products such as silverware and ormolu (a type of gilded bronze).

Working Practices

Between the 1760s and 1850, the nature of work transitioned from a craft production model to a factory-centric model. Textile factories organized workers’ lives much differently than did craft production. Handloom weavers worked at their own pace, with their own tools, and within their own cottages. Factories set hours of work and the machinery within them shaped the pace of work. Factories brought workers together within one building to work on machinery that they did not own. They also increased the division of labor, narrowing the number and scope of tasks. The work-discipline was forcefully instilled upon the workforce by the factory owners.

The early textile factories employed many children. In England and Scotland in 1788, two-thirds of the workers in 143 water-powered cotton mills were children. Sir Robert Peel, a mill owner turned reformer, promoted the 1802 Health and Morals of Apprentices Act, which was intended to prevent pauper children from working more than 12 hours a day in mills. Children started in the mills at around the age of four, working as mule scavengers under the working machinery until they were eight. They progressed to working as little piecers until they were 15. During this time they worked 14 to 16 hours a day, often physically abused. By 1835, the share of the workforce under 18 years of age in cotton mills in England and Scotland had fallen to 43%. About half of workers in Manchester and Stockport cotton factories surveyed in 1818 and 1819 bagan work at under ten years of age. Most of the adult workers in cotton factories in mid-19th-century Britain started as child laborers. The growth of this experienced adult factory workforce helps to account for the shift away from child labor in textile factories.

Societal Impact

While child labor was common on farms and under the putting-out system, historians agree that the impact of the factory system and the Industrial Revolution on children was damaging. In the industrial districts, children tended to enter the workforce at younger ages. Many of the new factory owners preferred to employ children as they viewed them as more docile and their wages were lower (10-20% of what was paid to male adult workers, while adult women made about 25% of an adult male salary). Although most families channeled their children’s earnings into providing a better diet for them, the physical toll of working in the factories was too great and led to detrimental outcomes for children. Child laborers tended to be orphans, children of widows, or from the poorest families. Cruelty and torture was enacted on children by master-manufacturers to maintain high output or keep them awake. The children’s bodies become crooked and deformed from the work in the mills and factories.

Prior to the development of the factory system, in the traditional marriage of the laboring class, women would marry men of the same social status and marriage outside this norm was unusual. Marriage during the Industrial Revolution shifted from this tradition to a more sociable union between wife and husband in the laboring class. Women and men tended to marry someone from the same job, geographical location, or social group. The traditional work sphere was still dictated by the father, who controlled the pace of work for his family. However, factories and mills undermined the old patriarchal authority. Factories put husbands, wives, and children under the same conditions and authority of the manufacturer masters.

Factory workers typically lived within walking distance to work until the introduction of bicycles and electric street railways in the 1890s. Thus the factory system was partly responsible for the rise of urban living, as large numbers of workers migrated into the towns in search of employment in the factories. Until the late 19th century, it was common to work at least 12 hours a day, six days a week in most factories, but long hours were also common outside factories.

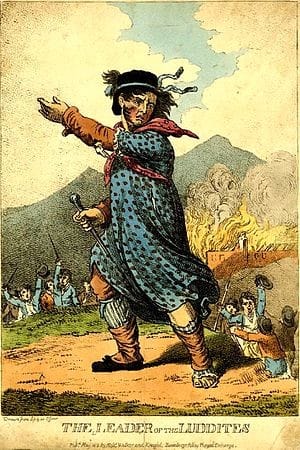

The transition to industrialization was not without opposition from the workers, who feared that machines would end the need for highly skilled labor. For example, a group of English workers known as Luddites formed to protest against industrialization and sometimes sabotaged factories. They continued an already established tradition of workers opposing labor-saving machinery. Numerous inventors in the textile industry, such as John Kay and Samuel Crompton, suffered harassment when developing their machines or devices. However, in other industries the transition to factory production was not so divisive.

The Leader of the Luddites, engraving of 1812, author unknown.

Although the Luddites feared above all that machines would remove the need for highly skilled labor, one misconception about the group is that they protested against the machinery itself in a vain attempt to halt progress. As a result, the term has come to mean a person opposed to industrialization, automation, computerization, or new technologies in general.

The overall impact of the factory system and the Industrial Revolution more on adults has been the subject of extensive debate among historians for over a century. Optimists have argued that industrialization brought higher wages and better living standards to most people. Pessimists have argued that these gains have been over-exaggerated, wages did not rise significantly during this period, and whatever economic gains were actually made must be offset against the worsening health and housing of the new urban sectors. Since the 1990s, many contributions to the standard of living debate has tilted towards the pessimist interpretation.

One of the best -known accounts of factory worker’s living conditions during the Industrial Revolution is Friedrich Engels’ The Condition of the Working Class in England in 1844. Engels described backstreet sections of Manchester and other mill towns, where people lived in crude shanties and shacks, some not completely enclosed, some with dirt floors. These shanty towns had narrow walkways between irregularly shaped lots and dwellings. There were no sanitary facilities. Population density was extremely high. Eight to ten unrelated mill workers often shared a room with no furniture, and slept on a pile of straw or sawdust. Disease spread through a contaminated water supply.

By the late 1880s, Engels noted that the extreme poverty and lack of sanitation he wrote about in 1844 had largely disappeared. Since then, the historical debate on the question of living conditions of factory workers has remained controversial. While some have pointed out that living conditions of the poor workers were tragic everywhere and industrialization slowly improved the living standards of a steadily increasing number of workers, others concluded that living standards for the majority of the population did not grow meaningfully until the late 19th and 20th centuries and that in many ways workers’ living standards declined under early capitalism.