Seating Suspension System For Furniture

What is Dymetrol®?

Acme Mills’ seating support system, Dymetrol® is a high performance suspension fabric. It is available in a range of firmness levels that allows seating constructions to meet specific deflection, comfort and durability requirements for furniture designs.

Dymetrol® provides all the comfort and durability of traditional seating suspensions while reducing the amount of bulky foam used and replacing springs, wires, clips, insulator pads, decking fabric and webbing. Chairs, sofas and love seats that use Dymetrol® fabric weigh less, require fewer materials and can be assembled faster. All of these advantages result in cost savings.

A few years ago, think profile seating was considered impractical. Now, it can be constructed in comfortable and contemporary designs.

Dymetrol is the Design Alternative for:

- Creative styling

- Greater design flexibility with complex shapes

- Consistent recovery

- Reduction of assembly costs

- Excellent dimensional stability as well as outstanding comfort and durability

- Eliminates creep / sag

Product Description

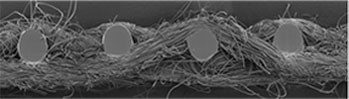

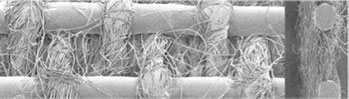

Dymetrol® fabric is a strong, elastic material that can be attached to wood, plastic or metal frames. Dymetrol® is woven with high-strength elastomeric monofilaments and polyester spun yarn that works together to create a support system that is comfortable and durable. Its most important feature is eliminating creep and maintaining consistent resilience (recovery) over many years of service.

Key Benefits

The superior attributes of Dymetrol® over traditional materials supplied by other fabric companies are best described by its many benefits to furniture designers and manufacturers.

Designers

Dymetrol® provides the freedom to create high comfort contemporary or traditional-styled furniture that can be economically produced.

- Creative styling

- Greater design flexibility with complex shapes

- Consistent recovery

- Reduction of assembly costs

- Excellent dimensional stability as well as outstanding comfort and durability

- Eliminates creep / sag

Manufacturers

Dymetrol® fabric replaces multiple materials (springs, clips, tie wires, insulators, decking fabric) with a single item. It also allows for reduction of foam required for the desired contour.

Furthermore, it permits cost reduction in labor and working capital and better use of working floor space, all affecting the manufacturer’s bottom line profit.

- Purchasing: A single support system dramatically reduces the number of purchase requisitions, purchase orders, vendor contacts, mailing supplies, purchase order acknowledgements, purchase order tracking and price change verifications found in stocking the wide variety of traditional seating materials.

- Receiving Department: Reduces paperwork, packing lists, receiving reports and number of deliveries. Material handling equipment and receiving room space are also reduced.

- Warehouse: Significantly reduces the floor space required to store traditional materials and the associated paperwork, labor and equipment to sequence material to the production floor.

- Upholstery Department: Production floor workstation density can be increased utilizing space previously used for material storage. Productivity is increased with fewer components to assemble. Pattern-cut panels allow consistent assembly of virtually any shape.

Our Acme engineers work closely with seat designers to provide all the technical assistance and prototyping needed to make a seamless transition into using the new material.