At Acme Mills, we understand that in the medical and pharmaceutical fields, comfort, hygiene, and functionality are not luxuries—they are requirements. That’s why our engineering team has devoted decades to advancing materials that meet the high standards of the healthcare industry. One of the standout innovations in our portfolio is our Contour Spacer Fabrics.

These three-dimensional, breathable fabrics have been designed specifically to improve patient care and enhance the performance of medical equipment. Our spacer fabric solutions bring together advanced material science and compassionate design—offering support, airflow, and reliability across a range of clinical applications.

Engineered for Healthcare: Why Spacer Fabrics?

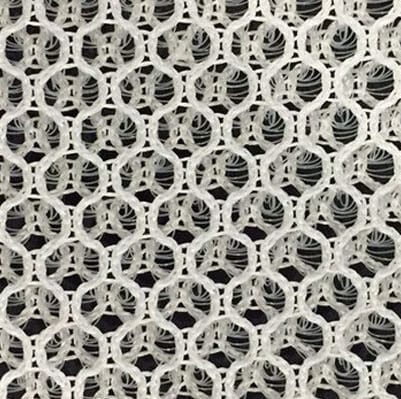

Spacer fabrics are constructed using two outer textile layers connected by vertical spacer yarns. This creates a unique structure that promotes air circulation, moisture management, and cushioning, while maintaining shape and durability over time.

These qualities make them ideal for sensitive and high-touch applications where patients and medical professionals rely on materials that deliver both comfort and clinical performance. Let’s explore where and how Acme Mills’ spacer fabrics are making a difference.

1. Hospital Mattresses: Enhancing Patient Comfort and Safety

In hospital settings, mattresses must strike a delicate balance: they must provide sufficient support to prevent bedsores, while also allowing heat and moisture to dissipate to keep patients comfortable during extended stays.

Our spacer fabrics for hospital mattresses are engineered to do exactly that. The breathable design improves air circulation, reducing the buildup of heat and moisture—two key contributors to pressure ulcers. This makes them ideal for pressure relief surfaces in acute care, long-term care, and post-operative recovery environments.

Combined with antimicrobial treatments or water-repellent finishes, these materials can be further optimized to enhance hygiene and prolong product lifespan.

2. Orthopedic Supports: Flexible, Lightweight, and Durable

Orthopedic devices—from knee braces to neck collars—must provide firm support while also being flexible and comfortable enough for all-day wear. Traditional padding materials can trap heat, irritate the skin, or lose their shape over time.

Our spacer fabrics for orthopedic supports offer a superior alternative. They’re lightweight, breathable, and easily conform to body contours without sacrificing structural integrity. Whether integrated into post-surgical braces or sports recovery devices, our materials improve comfort and reduce friction against the skin, promoting better patient compliance and recovery outcomes.

And because we can customize thickness, elasticity, and surface finish, we can match the exact requirements of your product.

3. Wheelchair Cushions: Pressure Relief Meets Ventilation

Long-term wheelchair users face unique challenges when it comes to pressure management and skin integrity. That’s why we’ve developed spacer fabric solutions specifically for wheelchair cushions, which need to offer both cushioning and ventilation.

Our materials reduce pressure points while promoting air circulation, minimizing the risk of heat buildup and skin irritation. This improves comfort for users who spend many hours seated each day—often in high-pressure zones that require consistent offloading and temperature control.

Spacer fabrics maintain their structure even under constant use, making them a reliable choice for cushions that need to perform day in and day out.

4. Medical Device Padding: Precision Comfort for High-Touch Areas

Medical equipment, from diagnostic imaging systems to physical therapy tools, often involves contact points that require soft, protective padding. Whether it’s a headrest on an MRI table or arm support on a dialysis chair, the materials used must be gentle, cleanable, and able to endure repeated use.

Spacer fabrics offer the perfect combination of soft cushioning, shape retention, and breathability for these high-touch applications. They help reduce patient discomfort during long procedures and can be customized with antimicrobial finishes to maintain a sanitary environment.

The ability to mold, cut, and finish these fabrics in various densities makes them a flexible option for OEMs designing next-generation diagnostic and therapeutic equipment.

Designed for Healthcare. Built by Acme Mills.

Every textile we manufacture for the medical industry is guided by one principle: patient well-being first. Our Contour Spacer Fabrics are developed with this mission in mind, helping our partners create healthcare solutions that deliver measurable improvements in comfort, performance, and safety.

We work closely with product developers, OEMs, and healthcare providers to tailor solutions to the exact needs of the application. Whether you need flame retardant, antimicrobial, or fluid-resistant finishes, our team can help engineer a fabric that meets your technical and regulatory requirements.

Let’s Build Better Care Together

At Acme Mills, we believe material innovation can improve outcomes—not just for patients, but for the professionals who care for them. Our spacer fabrics are more than just technical textiles—they’re a critical component of the future of healthcare design.

If you’re developing equipment, supports, or seating systems for the medical and pharmaceutical industries, we’d love to partner with you. Let us show you how Acme Mills’ spacer fabrics can elevate comfort, efficiency, and care quality—all in one engineered solution.