At Great Lakes Filters, we understand that filtration is essential for maintaining high-quality liquids in industrial and commercial applications. Whether it’s water used in manufacturing, oils in machining, or chemicals in processing plants, effective liquid filtration helps remove contaminants, improve efficiency, and ensure compliance with strict industry standards. As businesses strive for cleaner operations and sustainability, advanced filtration technologies have become more critical than ever.

The Importance of Liquid Filtration

Contaminated liquids can cause significant operational challenges, from equipment wear and downtime to product defects and regulatory violations. Filtration is a key solution to maintaining purity and performance across industries such as food and beverage, pharmaceuticals, automotive, and industrial manufacturing.

Advanced liquid filtration systems offer numerous benefits, including:

· Removing solid contaminants – Sediment, metal shavings, and other particulates can compromise product quality and damage machinery.

· Extending equipment lifespan – Cleaner liquids reduce wear and tear on pumps, nozzles, and processing equipment.

· Enhancing product consistency – Many industries require precise liquid composition, and effective filtration ensures a uniform end product.

· Ensuring regulatory compliance – Industries such as pharmaceuticals and food production must adhere to strict purity and safety regulations.

At Great Lakes Filters, we specialize in providing tailored filtration solutions that keep operations running smoothly while ensuring product integrity.

Common Applications of Liquid Filtration

Different industries rely on filtration to maintain liquid quality and meet operational requirements. Some of the most common applications include:

1. Industrial Water Filtration

Water used in manufacturing processes must be free from contaminants to prevent equipment damage and ensure product consistency. Filtration removes sediments, chlorine, and other impurities in cooling systems, boilers, and wastewater treatment facilities.

2. Oil and Coolant Filtration

In machining and metalworking, clean lubricants and coolants are essential for extending tool life and improving product finish. Filtration systems remove debris, tramp oil, and metal particles, reducing waste and maintenance costs.

3. Food and Beverage Processing

High-quality liquid filtration is vital in the food and beverage industry to maintain hygiene and safety. From juice and dairy processing to brewing and bottling, filtration removes unwanted particles while preserving flavor and consistency.

4. Pharmaceutical and Chemical Processing

Pharmaceutical production requires precise liquid filtration to remove bacteria, endotoxins, and other impurities. Likewise, chemical manufacturing depends on advanced filtration to maintain purity and process efficiency.

Types of Liquid Filtration Systems

Selecting the right filtration system depends on the liquid type, level of contamination, and industry requirements. Some of the most effective liquid filtration solutions include:

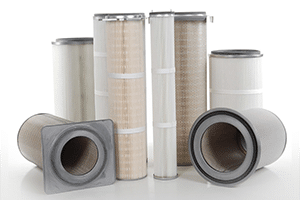

· Cartridge Filters – Ideal for fine particle removal in water, chemicals, and food processing.

· Bag Filters – Used in high-flow applications to capture solid contaminants in industrial fluids.

· Membrane Filters – Essential for ultra-pure applications such as pharmaceuticals and microelectronics.

· Depth Filters – Provide multi-layer filtration for heavy-duty industrial use.

· Centrifugal Separators – Remove heavy solids from liquids without the need for filter media.

At Great Lakes Filters, we offer an extensive range of filtration solutions designed to meet the specific needs of different industries.

How to Choose the Right Liquid Filtration System

When selecting a liquid filtration system, businesses should consider:

· Contaminant size and type – Understanding the particles or impurities in the liquid helps determine the best filtration method.

· Flow rate and system capacity – The filtration system should efficiently handle the required volume without compromising performance.

· Regulatory and industry standards – Compliance with FDA, EPA, or other regulations is crucial for safety and quality assurance.

· Cost and maintenance – Durable, long-lasting filtration solutions reduce operational costs and minimize downtime.

With our expertise, we help clients choose the most efficient and cost-effective filtration systems for their needs.

Partner with Great Lakes Filters for Advanced Liquid Filtration

As a trusted provider of industrial filtration solutions, Great Lakes Filters offers:

· Custom-engineered filtration systems designed for specific applications.

· High-performance materials that improve efficiency and longevity.

· Expert guidance to ensure optimal filtration for any liquid process.

By investing in the right filtration technology, businesses can enhance liquid quality, protect equipment, and comply with industry standards. If you’re looking for reliable filtration solutions, contact Great Lakes Filters today.